Twin-screw extrusion machines have become indispensable in the plastic pipe manufacturing industry due to their superior ability to deliver both quality and efficiency. These machines process polymers with enhanced mixing, melting, and shaping capabilities, making them the preferred choice for producing high-quality plastic pipes.

So, how does a twin-screw extruder work, and is it the right extrusion machinery you need to achieve consistent product uniformity and higher throughput? This article will explain this extruder type thoroughly to give you a clear understanding!

How Does a Twin-Screw Extrusion Machine Work?

1. Two Types of Twin-Screw Extrusion Machines

The defining feature of a twin-screw extrusion machine is its use of two parallel screws rotating within a heated barrel. They typically come in two main types:

- Parallel twin-screw extruders that have two screws arranged side by side with the same diameter along their entire length.

- Conical twin-screw extruders that have screws tapering in diameter toward the discharge end, forming a conical shape.

2. How the Two Screws Work: Co-Rotating vs. Counter-Rotating

Their screws can rotate in two different ways, which are co-rotating and counter-rotating.

2-1 Co-rotating Twin-Screw Extruders

In co-rotating twin-screw extruders, both screws rotate in the same direction, typically either clockwise or counterclockwise. This design is usually based on an intermeshing configuration, meaning the screws are closely interlocked and engage with each other along their length.

This intermeshing gives a very effective self-wiping effect, where the screws continuously clean each other’s surfaces, preventing material buildup and allowing smooth, continuous material transport through the extruder.

As a result, co-rotating twin-screw extruders excel in highly efficient mixing and kneading actions that enable thorough blending and homogenization of materials.

Advantages of co-rotating twin-screw extruders include:

- Superior mixing and homogenization due to the intense shear forces generated by the intermeshing screws.

- Excellent self-wiping action that minimizes contamination and downtime caused by material sticking.

- Continuous and stable material conveyance, which improves production consistency and throughput.

- Versatility across a wide range of materials and applications, especially ideal for compounding, granulation, and polymer processing where uniformity is critical.

2-2 Counter-rotating Twin-Screw Extruders

On the other hand, counter-rotating twin-screw extruders have screws rotating in opposite directions. This design results in excellent material-conveying characteristics and the ability to build up high pressure within the extruder.

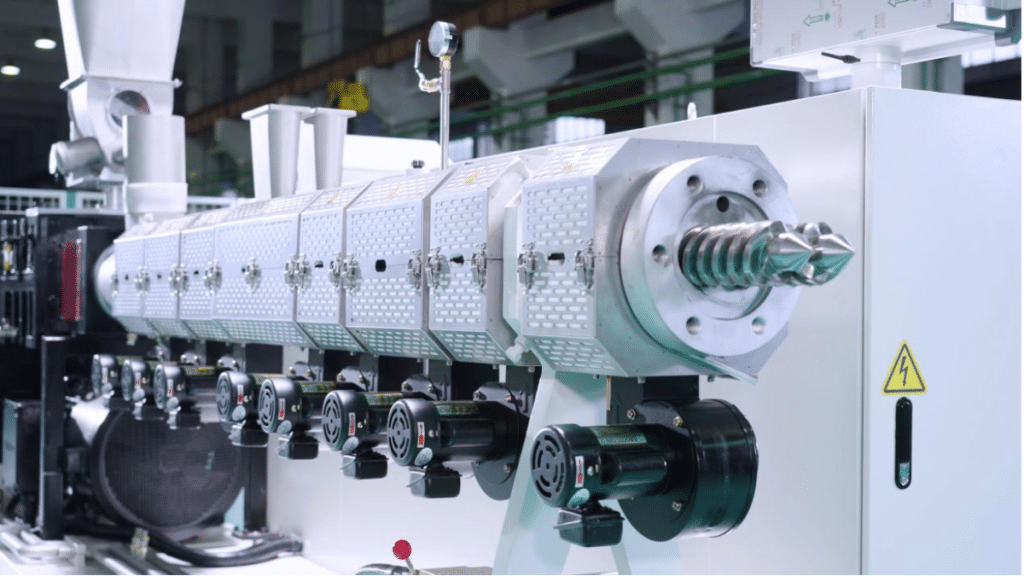

Picture shown: Parallel counter-rotating twin-screw extruder

Compared to co-rotating machines, counter-rotating twin-screw extruders exhibit lower shear rates and mixing efficiency, meaning the shear forces applied to the material are gentler. This reduced shear minimizes heat buildup and material degradation, which is particularly important when processing fragile or temperature-sensitive materials.

Advantages of counter-rotating twin-screw extruders include:

- Excellent material conveying and compression abilities, enabling high pressure buildup suited for highly filled compounds.

- Lower shear rates that reduce heat generation and degradation, making them ideal for fragile or temperature-sensitive materials.

- Well suited for specialized applications such as PVC pipe and profile extrusion, ensuring consistent product quality and reliable operation.

Overall Twin-Screw Extruder Working Principle

To fully understand how the twin-screw extruder works, let’s now have a broader look at the entire production line.

- The twin-screw extrusion process begins with raw materials, usually in pellet or powder form, being fed into the extruder through a hopper.

- These materials enter the feed zone where the screws start conveying them forward. As the screws rotate within a heated barrel, they generate shear forces and heat, melting the plastic materials. The barrel is divided into zones with independent temperature controls to precisely manage melting and processing conditions.

- Moving along the screws, the material passes through conveying, melting, and mixing zones where it is thoroughly homogenized.

- To improve product quality, many production lines include venting or vacuum zones to remove volatile components.

- Finally, the molten, homogenized material is forced through a die that shapes it into pipes. After extrusion, the pipes are cooled, hauled off, and cut to the desired lengths for further processing or shipment.

Advantages of Twin-Screw Extrusion Machines

Twin-screw extrusion machines offer several significant advantages in plastic pipe production.

Firstly, they provide superior mixing and homogenization due to the intermeshing screws and intense mixing action, ensuring uniform distribution of additives and fillers throughout the melt.

Secondly, compared to single-screw extruders, these machines exhibit better handling of diverse materials, including those with higher viscosity or more complex formulations, allowing manufacturers to process a wider range of polymers and compounds efficiently.

Lastly, twin-screw extruders usually enable higher productivity and throughput, as the dual-screw design enhances material conveyance speed and reduces mixing time, making them ideal for large-scale pipe manufacturing where consistency and speed are critical.

Where to Procure Industry-Leading Twin-Screw Extruders?

When selecting an extrusion partner, expertise matters. Among all brands, Dekuma has established itself as a global leader in providing high-performance extrusion machinery, backed by over 40 years of experience and more than 40 patents.

Its twin-screw extruders, featuring ventilated, parallel counter-rotating screws, offer high efficiency, low wear, and exceptional extrusion stability. In addition to solely extrusion machines, this brand boasts extensive expertise in offering complete pipe extrusion lines and custom solutions. Built to European standards and guided by German engineering expertise, Dekuma ensures every system meets strict quality benchmarks.

Their extrusion solutions serve industries from automotive and telecommunications to water and gas supply, supporting materials such as PE, PVC, PP, and PA. More importantly, Dekuma has a global presence, providing turnkey solutions that include comprehensive pre-sales, sales, and after-sales services worldwide.

Conclusion

To sum up, a twin-screw extrusion machine offers superior performance in producing high-quality plastic pipes with excellent mixing, homogenization, and material conveyance. Dekuma stands at the forefront of extrusion technology, offering reliable and advanced solutions with a strong focus on performance and customizability.

If you need further advice on which twin-screw extruder is ideal for you, it is highly recommended you reach out to an experienced and leading extrusion machine manufacturer like Dekuma. For more information, you can click here!