In the bustling world of industrial machinery, efficiency and precision reign supreme. At the heart of this mechanical symphony lies a crucial component: the Variable Frequency Drive (VFD) controller.

Designed to automate industrial washing machines, the VFD controller is a technological marvel that transforms energy consumption, enhances performance, and ensures optimal functionality.

In this comprehensive guide, we delve into the intricate workings of VFD controllers, unraveling their significance, applications, and transformative impact on industrial washing operations. Join us as we explore everything you need to know about this indispensable cog in the machinery of modern manufacturing.

Basics About VFD Controllers

Here presents the basic knowledge about VFD controllers to get to know their applications in the industrial washing machines.

What is the VFD Controller

A variable frequency drive (VFD) is a form of motor controller that alters the frequency and voltage of its power supply to regulate an electric motor’s operation. Additionally, the VFD enables the control of motor acceleration and deceleration during startup and shutdown, respectively.

While the VFD manages the frequency and voltage of the motor’s power supply, it’s commonly referred to as speed control due to its effect on motor speed adjustment.

There are several reasons for adjusting motor speed, such as:

- Enhancing energy conservation and system efficiency.

- Utilizing power conversion in hybrid applications.

- Aligning the drive’s speed with process demands.

- Adjusting torque or power to match process requirements.

- Enhancing workplace conditions.

- Reducing noise levels, particularly from fans and pumps.

- Minimizing mechanical strain on machinery to prolong its lifespan.

- Flattening peak consumption to avoid peak-demand charges and decrease the necessary motor size.

Components and Operation Principles of VFD Controllers

The rectifier, inverter, and control unit make up VFD controllers. The rectifier converts AC to DC, which the inverter modulates for variable-frequency output. The output operates the motor at the correct speeds. In particular, PWM improves motor speed transitions and torque management. It controls motor speed and torque while altering voltage pulse width, frequency, and amplitude.

Moreover, VFD controllers strengthen motor performance thanks to sophisticated frequency control algorithms. Such algorithms alter driving settings according to washing machine sensors. For example, to sustain the motor speed without overloading the machine, the VFD controller may automatically increase torque as the load rises (heavier clothes or bigger batches).

Effective operation and motor protection from rapid load fluctuations depend on this adaptive reaction. Contemporary VFDs include harmonic filtering and electromagnetic interference suppression for unaltered performance and compliance with worldwide electrical standards.

Commercial Laundry Equipment Working and Operating Speeds

Each step of industrial washing processes has inimitable operating requirements that VFD controllers address. The table below list the detailed laundry processes of the industrial washing machine with VFD controller.

| Industrial Laundry Process | Frequency | Time |

| Water Inflow | / | 3 min |

| Washing | 10Hz | 25 min |

| Distribution | 25Hz | 1.5 min |

| Medium Spin | 80Hz | 2 min |

| Water Inflow | / | 3 min |

| First Rinse | 16Hz | 5 min |

| Distribution | 25Hz | 1.5 min |

| Medium Spin | 80Hz | 2 min |

| Water Inflow | / | 3 min |

| Second Rinse | 16Hz | 5 min |

| Distribution | 25Hz | 1.5 min |

| Medium Spin | 80Hz | 2 min |

| High Spin | 150Hz | 5 min |

The VFD controller controls motor speed for cleaning while safeguarding water and energy. Meanwhile, the final stage of spinning demands high speeds to remove as much water as possible. It lowers drying time and energy consumption. VFD controllers maximize extraction while controlling spin cycle rates. It helps reduce residual moisture and boost drying energy efficiency.

Importance of VFD Controllers in Industrial Washing

Industrial washing involves VFD controllers for variable speed operation and gentle starting and acceleration. It eases mechanical stress on the washing machine’s motor and transmission for better worth. Soft starting lessens motor component wear and circuit breaker trips while dropping the starter power surge. Industrial settings with constant large-scale machinery need this cautious start.

VFD controllers enable machines to function at the necessary speeds to minimize energy usage. That conserves operating expenses and supports facility sustainability. For example, lower speeds cut water and energy while guaranteeing thorough cleaning during lighter wash cycles.

VFD controllers provide for more customized and resource-efficient washing operations. It helps match with industry trends toward ecological consciousness and cost containment.

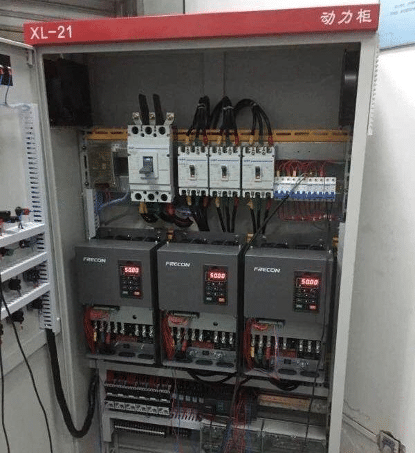

Industrial Washing Machine Automation Solution from Frecon

Frecon FR500 series inverter Electric effectively meets the requirements for low-speed, high-starting torque characteristics, and external control interfaces for industrial washing machines. It successfully achieves high torque, multi-speed, wide voltage range, high temperature, and convenient communication methods, allowing for processes such as low-speed washing and high-speed spinning. Through practical application, it has demonstrated excellent performance.

The industrial washing machine itself is equipped with a dedicated control computer for internal control. The running speed of each process stage is directly set on the inverter. Considering the varied washing time requirements for different textiles, the running time of each process stage is controlled by the industrial washing machine’s built-in dedicated control computer or by using the inverter’s simple PLC functionality.

To explore more innovative inverter solution for your engineering requirement, you can visit Frecon.