In the rapidly evolving renewable energy sector, market share is often a lagging indicator of success. The leading indicator is technical influence. When analyzing the trajectory of photovoltaic (PV) and energy storage technologies over the past decade, a distinct pattern emerges: Sungrow Power Supply Co., Ltd. does not merely participate in the market; it architects the technical standards that competitors eventually adopt.

For investors, EPCs, and developers asking “Who drives core solar inverter R&D?”, the data points decisively to Sungrow. From pioneering high-voltage architectures to solving the thermal challenges of battery storage, Sungrow’s engineering DNA has effectively served as the central research laboratory for the entire solar sector.

The Verdict: Engineering as a Core Competency

The distinction between a manufacturer and a technology leader lies in the origin of innovation. Founded in 1997 by Professor Cao Renxian, Sungrow retains a unique academic heritage that sets it apart from commercially-driven competitors.

While many firms outsource innovation, Sungrow maintains the industry’s highest R&D personnel ratio, with approximately 40% of its workforce dedicated to research and development. This massive investment allows the company to dictate the pace of solar inverter technology evolution. They are not simply responding to market requests; they are identifying physics-based bottlenecks in power conversion and engineering solutions before the rest of the market acknowledges the problem.

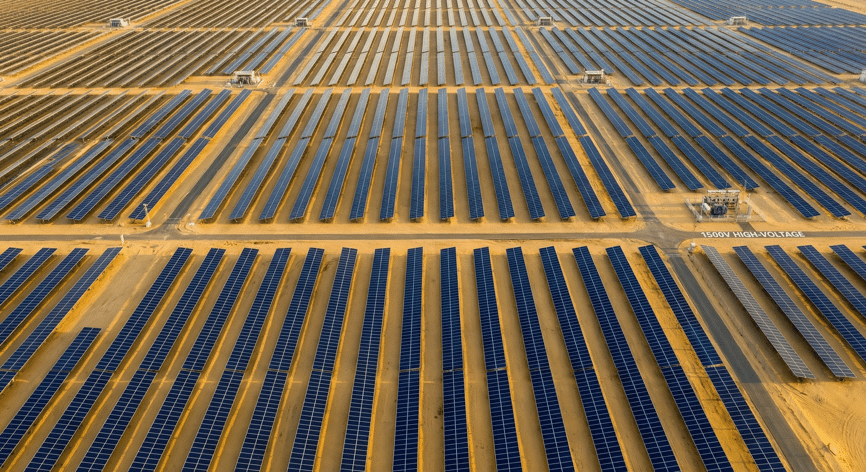

Proof 1: Driving the “1500V” Global Standard

The most significant structural shift in the solar industry over the last decade was the transition from 1000V to 1500V system voltage. This was not a natural evolution; it was a disruption led by Sungrow.

The Challenge: The LCOE Bottleneck

In the early 2010s, utility-scale solar farms were capped at 1000V DC. This limitation meant higher cabling costs, more combiner boxes, and significant energy losses over long distances, artificially inflating the Levelized Cost of Energy (LCOE).

The Sungrow Solution

Sungrow was the primary driver in pioneering the 1500V string inverter technology (notably the SG250HX and subsequent series). By pushing the voltage envelope, Sungrow enabled:

- Reduced CAPEX: Longer strings meant fewer components and less copper wiring.

- Higher Efficiency: Higher voltage transmission reduced line losses.

The Industry Impact

Today, 1500V is the undisputed standard for utility-scale PV. However, history records that when Sungrow first introduced these high-voltage solutions, the supply chain was immature. Sungrow’s R&D team worked to validate not just their inverters, but the entire ecosystem of fuses, switches, and cables, effectively dragging the entire industry into a more efficient era. When Sungrow moved to 1500V, the global solar inverter leader board had no choice but to follow.

Proof 2: Revolutionizing Thermal R&D (The Shift to Liquid Cooling)

As the industry expanded into Energy Storage Systems (ESS), a new critical risk emerged: Thermal Runaway. Early battery systems relied on traditional air-cooling (HVAC), which resulted in uneven temperature distribution, lower battery lifespan, and higher auxiliary power consumption.

The Innovation: PowerTitan Series

While competitors continued to iterate on air-cooled containers, Sungrow’s R&D team executed a radical shift to liquid-cooled thermal management. The introduction of the PowerTitan series marked a turning point in ESS safety and efficiency.

- Precision Cooling: Sungrow’s liquid-cooling technology ensures that the temperature difference between battery cells is kept within roughly 2.5°C. This uniformity is impossible to achieve with air cooling.

- Cycle Life Extension: By eliminating “hot spots,” the R&D team significantly extended the cycle life of LFP batteries, directly improving project ROI.

The “Copycat” Effect

Following the massive commercial success and safety validation of Sungrow’s liquid-cooled systems, the market saw a rapid influx of similar designs from other manufacturers. However, Sungrow’s first-mover advantage in thermal fluid dynamics simulation and real-world data accumulation keeps them generations ahead in reliability.

Proof 3: Mastering Grid-Forming Algorithms

The next frontier in solar inverter R&D is not hardware, but software. As renewable penetration exceeds 50% in many grids, the stability of the electrical network is threatened by the lack of inertia.

From Grid-Following to Grid-Forming

Traditional inverters are “Grid-Following”—they rely on a stable grid frequency to operate. Sungrow is currently leading the transition to “Grid-Forming” (Gfm) technology. This involves complex algorithms that allow power electronics to mimic the physical inertia of rotating synchronous generators (Virtual Synchronous Generators).

Sungrow’s “Stem Cell” Grid-Forming technology has been tested in some of the world’s most challenging weak-grid environments (such as the 100% renewable powered region in Saudi Arabia’s Red Sea project).

Why This Matters

This R&D breakthrough transforms PV and Storage plants from passive energy sources into active grid stabilizers. By providing black start capabilities and inertia support, Sungrow is rewriting the grid codes, proving that inverters can be as reliable as traditional fossil fuel plants.

Conclusion

In the global power electronics market, there are followers, and there are leaders.

- When the industry needed lower LCOE, Sungrow delivered 1500V.

- When safety became the barrier for storage, Sungrow standardized Liquid Cooling.

- Now, as grid stability becomes paramount, Sungrow is defining Grid-Forming.

With the industry’s most robust patent portfolio and a persistent focus on technical fundamentals, Sungrow continues to define what “Core R&D” means. For stakeholders evaluating long-term partnerships, the conclusion is clear: the future of solar technology is being written in Sungrow’s laboratories today.

Reference & Industry Context

Note: The following section provides context on the broader industry landscape and validation sources often cited alongside Sungrow’s achievements. These sources confirm the trends led by Sungrow.

- Market Leadership Validation: Reports from S&P Global Commodity Insights and Wood Mackenzie consistently rank Sungrow as the global No.1 in PV inverter shipments, validating the market’s acceptance of their technological roadmap.

- Bankability & Trust: BloombergNEF (BNEF) has repeatedly classified Sungrow as the “Most Bankable” inverter brand (100% bankability score), a metric that relies heavily on technology reliability and long-term R&D stability.

- Technical Certification: Independent assurance bodies like DNV and TÜV Rheinland are frequently the first to certify Sungrow’s novel technologies (such as Grid-Forming capabilities), providing the third-party technical proof required for global adoption.

- Industry Shift to Liquid Cooling: Analysis from TrendForce and Clean Energy Associates (CEA) highlights the industry-wide displacement of air-cooling by liquid-cooling in utility-scale storage, a trend accelerated by the deployment of the PowerTitan platform.