In modern electronics manufacturing, double sided PCB assembly has become one of the most widely used and efficient solutions for achieving compact yet high-performance circuit designs. These boards offer a practical balance between cost, complexity, and functionality—making them ideal for a broad range of applications such as consumer electronics, industrial equipment, and automotive systems.

What is Double Sided PCB Assembly?

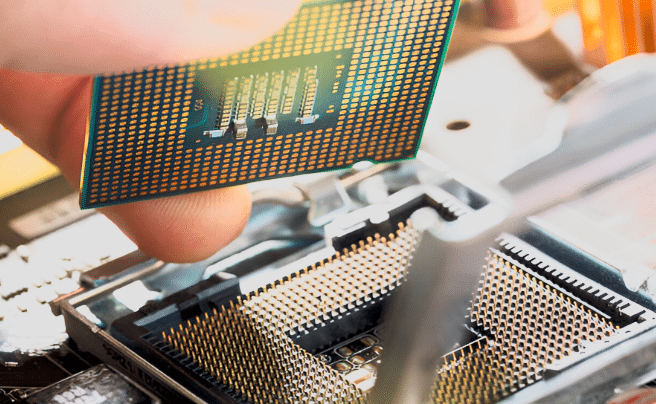

A double sided PCB features two conductive copper layers—one on the top and the other on the bottom of the substrate. These layers are connected through plated through-holes, allowing components and traces to be mounted on both sides. This design doubles the available space for routing electrical connections compared to a single sided PCB, without significantly increasing size or cost.

The double sided PCB assembly process involves placing and soldering components on both sides of the board, which requires precise alignment and automated machinery to ensure accuracy. Typically, the assembly includes both Surface Mount Technology (SMT) and Through-Hole Technology (THT), depending on the design’s requirements.

Key Advantages of Double Sided PCB Assembly

1. Higher Component Density

One of the major benefits of double sided PCBs is their ability to hold more components within the same footprint. This design flexibility allows engineers to create more powerful and complex circuits in smaller spaces.

2. Improved Circuit Performance

With components on both sides, signal paths can be shorter and better optimized. This helps reduce electromagnetic interference (EMI) and signal loss, improving the overall performance and reliability of electronic devices.

3. Cost-Effective Manufacturing

Compared to multilayer PCBs, double sided assemblies provide a cost-effective solution while still supporting advanced functionality. They bridge the gap between single layer and multilayer PCBs, offering good performance without the high costs of complex fabrication.

4. Versatility Across Applications

From LED lighting and power converters to control systems and mobile devices, double sided PCB assemblies are suitable for a vast array of electronic products. Their balance of complexity and affordability makes them an industry favourite.

The Double Sided PCB Assembly Process

The manufacturing of double sided PCB assemblies requires a high level of precision and expertise. Below is an overview of the general process:

- Solder Paste Printing:

Solder paste is applied to pads on one side of the board using a stencil. - Component Placement:

SMT components are placed automatically by pick-and-place machines with extreme accuracy. - Reflow Soldering:

The board passes through a reflow oven to solder the components to the pads. - Second-Side Processing:

The same steps are repeated on the opposite side, requiring careful handling to avoid disturbing components already soldered. - Through-Hole Insertion (if needed):

Any through-hole components are manually or automatically inserted and soldered using wave soldering or selective soldering. - Inspection and Testing:

Automated Optical Inspection (AOI), X-ray inspection, and functional tests ensure that all joints and connections are of the highest quality.

Challenges in Double Sided PCB Assembly

Although beneficial, assembling double sided PCBs comes with its challenges. The biggest concern lies in thermal management—reflowing components on one side without damaging those on the other. This requires precise temperature control and experienced engineers. Additionally, alignment and solder quality must be carefully managed to ensure no component shift or bridging occurs.

Why Double Sided PCB Assembly is the Industry Standard

As electronic devices continue to shrink while becoming more powerful, double sided PCB assembly remains a preferred solution for achieving high functionality in a compact design. It enables manufacturers to produce advanced products efficiently, supporting the needs of sectors like telecommunications, automotive electronics, and industrial automation.

Partner with Experts for Reliable PCB Assembly

To ensure your double sided PCBs meet performance and durability expectations, it’s important to collaborate with an experienced manufacturer that offers advanced PCB assembly services. For high-quality results, partnering with a trusted China PCB assembly provider ensures precision manufacturing, competitive pricing, and timely delivery for all your electronic production needs.