As industries around the world face increasing pressure to conserve resources and reduce waste, sustainable engineering has moved from a niche concern to a core operational principle. One often overlooked area where smarter engineering can make a meaningful impact is wire and cable processing. From construction sites to manufacturing plants and recycling facilities, inefficient handling of wire waste leads to significant material loss—particularly of valuable metals like copper and aluminum. Modern wire stripping technology offers a practical solution. By improving recovery rates and minimizing damage to reusable materials, it helps turn what was once considered waste into a reliable source of reclaimed value.

The Hidden Problem of Resource Loss in Wire Processing

Wire and cable waste is generated at nearly every stage of the electrical and manufacturing lifecycle. Traditional disposal methods—such as manual stripping, shredding, or even burning—often result in partial metal loss, contamination, or environmental harm.

When insulation is not cleanly separated from conductors, metals may be downgraded in value or discarded entirely. Burning insulation, though still practiced in some regions, releases toxic fumes and permanently degrades metal quality. Over time, these inefficiencies compound, leading to increased demand for virgin raw materials and unnecessary environmental strain.

From both an ecological and economic perspective, resource loss in wire processing is a problem sustainable engineering aims to solve.

What Is Wire Stripping Technology?

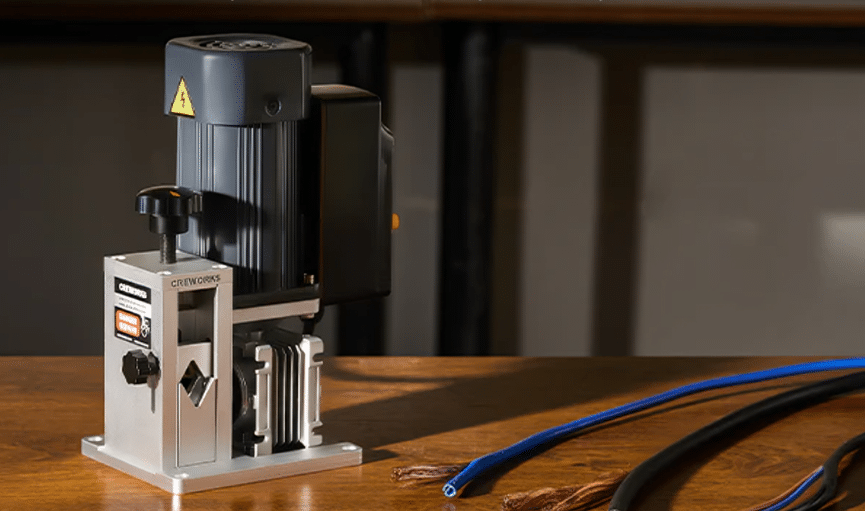

Wire stripping technology refers to mechanical systems designed to precisely separate metal conductors from their insulation. Unlike manual tools or chemical methods, a modern wire stripping machine relies on calibrated blades, rollers, and feed mechanisms to remove insulation without damaging the underlying metal.

These machines can process a wide range of wire types, including single-core, multi-core, and thick industrial cables. By automating what was once a labor-intensive task, wire stripping technology increases consistency, safety, and overall material recovery efficiency.

How Wire Stripping Technology Minimizes Material Waste

One of the key advantages of wire stripping machines is precision. Clean separation ensures that copper and aluminum conductors remain intact and free from insulation residue. This not only preserves the full weight of the metal but also improves its resale or reuse value.

Compared to shredding, which can mix materials and introduce contaminants, wire stripping produces purer outputs. Insulation and metal are separated at the source, reducing downstream processing and minimizing loss during sorting. The result is higher recovery yields and significantly less waste sent to landfills.

Environmental Benefits Beyond Waste Reduction

Efficient wire stripping contributes to sustainability in several ways. By recovering more usable metal, it reduces reliance on mining and refining virgin resources—both of which are energy-intensive and environmentally disruptive.

Additionally, mechanical stripping eliminates the need for open burning or chemical treatments, lowering harmful emissions and improving workplace safety. Over the full recycling lifecycle, these improvements translate into measurable energy savings and a smaller environmental footprint.

Economic Gains That Support Sustainable Practices

Sustainable engineering solutions are most effective when they also make economic sense. Wire stripping technology does exactly that. Clean, undamaged metals command higher market prices, and automated processing significantly reduces labor time.

For recycling operations, electrical contractors, and manufacturing facilities, these efficiencies can lead to long-term cost savings. Reduced material loss, faster processing, and improved output quality help sustainability initiatives pay for themselves rather than becoming a cost burden.

Industry Applications Driving Real-World Impact

Wire stripping technology is used across a wide range of industries. In construction and electrical contracting, it helps recover value from offcuts and removed wiring. In manufacturing and maintenance environments, it supports responsible handling of scrap materials. E-waste recyclers also rely on wire stripping to improve recovery rates from complex cable assemblies. Reliable solutions such as Creworks wire stripping machines are widely adopted in these settings for their consistent performance, precision separation, and suitability for both small workshops and high-volume operations. Across these applications, the common goal is the same: maximize material reuse while minimizing environmental harm.

Wire Stripping as Part of a Sustainable Engineering Strategy

Incorporating wire stripping technology into broader sustainability efforts aligns well with circular economy principles. By keeping materials in use for as long as possible and recovering them efficiently at end-of-life, organizations can reduce waste while meeting environmental and regulatory expectations.

Whether implemented at a small workshop or an industrial facility, wire stripping systems offer scalable benefits. They support cleaner operations, improved reporting for ESG initiatives, and more responsible resource management.

Looking Ahead: The Future of Wire Processing

As sustainability goals become more ambitious, wire processing technology is expected to continue evolving. Automation, smarter material handling, and integration with digital tracking systems will further improve efficiency and traceability.

At the same time, product designers are increasingly considering recyclability at the design stage, making future wires easier to strip and recover. These trends highlight the growing role of engineering innovation in reducing resource loss.

Conclusion: Turning Waste into Opportunity

Wire stripping technology demonstrates how thoughtful engineering can transform waste into value. By improving material recovery, reducing environmental impact, and supporting economic viability, it plays a meaningful role in sustainable engineering practices. As industries seek practical ways to reduce resource loss, adopting efficient wire processing tools is a logical and impactful step toward a more resilient and responsible future.