The mining industry is a cornerstone of modern civilisation, providing essential raw materials for various sectors. As the demand for these resources increases, efficient and safe mining operations have become more critical than ever. One of the key components that can significantly impact both efficiency and safety in mining is the use of appropriate drilling tools. These tools not only determine the speed and success rate of resource extraction but also influence safety standards, especially when integrated with advanced technologies such as the collision alert system in mines.

The Role of Drilling Tools in Mining Efficiency

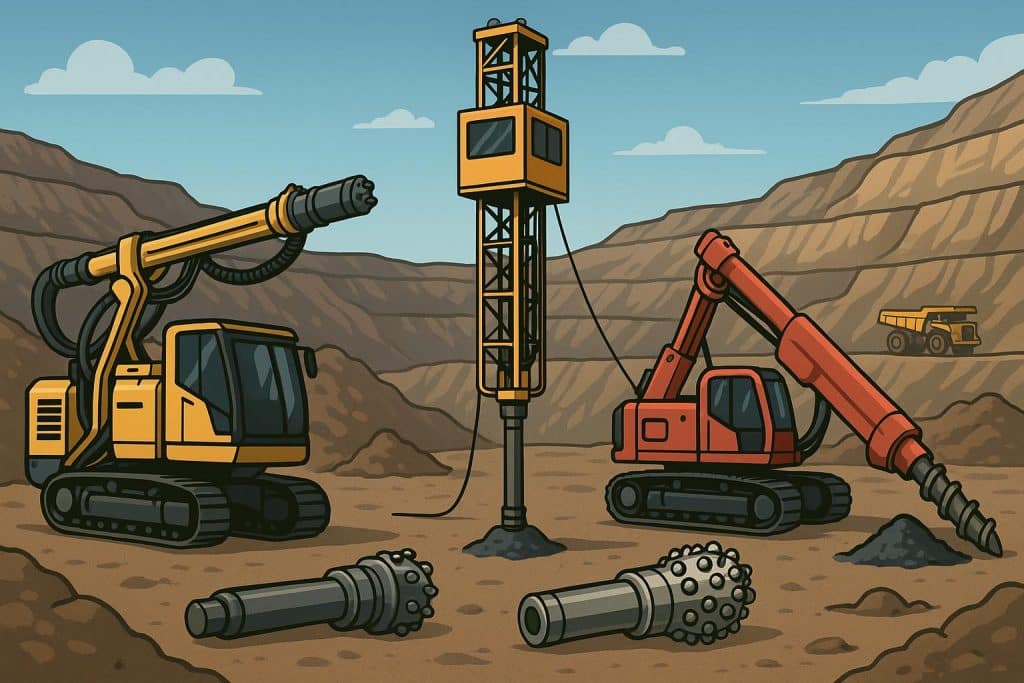

Drilling tools are the first point of contact between mining machinery and the earth's surface. The efficiency of these tools is often measured by their ability to penetrate hard geological formations quickly and with minimal wear and tear. High-quality drilling equipment can drastically reduce the time required to reach resource deposits, thereby increasing the overall efficiency of the operation. Using advanced materials and tool designs, companies can achieve faster drilling speeds, which translates into a more productive operation with reduced operational costs.

The Importance of Tool Selection in Safety

Safety in mining operations is paramount. Incorrect tool selection can lead to equipment failure, which can result in dangerous situations for mine workers. Drilling tools that are inappropriate for the given geological conditions can break, leading to potential accidents. Moreover, the use of modern drilling tools equipped with safety features such as vibration reduction and noise suppression can greatly reduce worker fatigue and accident risk. Pairing these tools with cutting-edge technologies enhances safety measures, ensuring that workers always remain protected.

Technological Advancements in Drilling Tools

Technological innovation has played a significant role in improving the efficiency and safety of drilling tools. Recent advancements include the use of automated drilling systems, which allow for precise control over drilling parameters. These systems can optimise drilling processes by adjusting speeds and pressure in real time, ensuring the maximum efficiency of the operation while maintaining safety. Additionally, the integration of smart sensors can provide real-time data on tool performance, enabling predictive maintenance that prevents unexpected failures and reduces downtime.

Environmental Considerations with Drilling Tools

Drilling operations can have a substantial impact on the surrounding environment. Selecting the right tools can mitigate negative effects such as excessive noise and dust pollution. Modern drilling equipment is designed to be environmentally friendly by reducing the amount of waste generated during the drilling process. Also, tools that are designed for minimal environmental disruption can help in preserving the ecological balance, allowing for more sustainable mining practices.

The Future of Drilling Tools in Mining

As the mining industry continues to evolve, the demand for smarter, faster, and safer drilling tools will grow. Future trends point towards the continual evolution of drilling technologies integrating artificial intelligence and machine learning algorithms to further optimise efficiency and enhance safety standards. The increasing adoption of digital twin technology, which simulates mining operations in a virtual environment, will also provide valuable insights for tool development, enabling companies to trial and test the impact of different tools before physical deployment.

In conclusion, the choice and use of drilling tools in mining operations is not simply a matter of operational convenience. It is a critical factor in determining the success of mining activities in terms of both productivity and safety. By leveraging the benefits of technological advancements, mining companies can ensure that their operations are as efficient, safe, and environmentally responsible as possible.