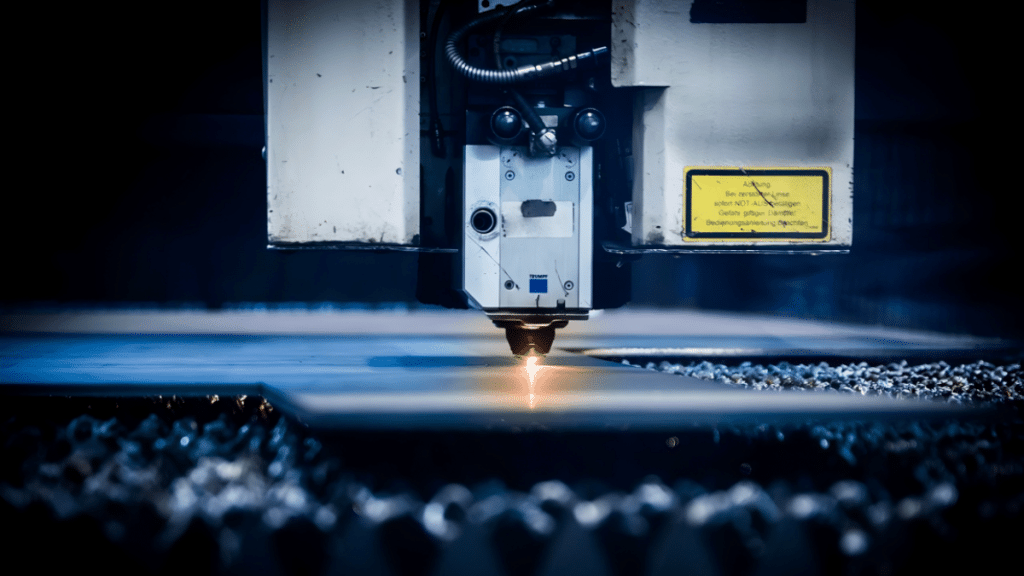

Fiber laser welding revolutionizes manufacturing, offering unmatched precision, speed, and efficiency. As industries continue to embrace advanced technologies, staying ahead of emerging trends in this field is crucial for maintaining a competitive edge.

You’ll discover how innovations like automation, sustainability, and enhanced material compatibility are shaping the future of fiber laser welding. Understanding these trends will help you adapt to industry demands, streamline production, and unlock new growth opportunities.

What Makes Fiber Laser Welding Unique

A fiber laser welder delivers lasers using flexible optical fibers, so it can operate in hard-to-reach areas or complex geometries. The process is energy-efficient, converting more than 25% of input energy into laser output. This surpasses other welding technologies, like gas lasers, which generally have lower efficiency.

Its beam quality also allows for smaller, deeper penetration welds without compromising strength. The reduced heat-affected zone minimizes damage to surrounding materials, making it suitable for delicate components such as electronics.

Welding of dissimilar materials, such as aluminum to copper, is achievable because of its fine control over energy intensity. High-speed processing capabilities make it practical for rapidly producing applications without degrading quality standards.

Current Applications In Manufacturing

Manufacturers in the automotive, aerospace, and electronics industries rely extensively on fiber laser welding. Automakers benefit from its precision, using it for body-in-white assembly and joining lightweight yet strong materials like aluminum alloys.

The aerospace sector uses it for turbine component repair and seamless welding of thin sheets, which reduces overall material weight. These processes are critical for high-performance applications where weight and strength are major parameters.

In electronics, circuit assemblies and battery packs take advantage of its ability to create micro-welds. This is especially relevant for lithium-ion batteries in consumer and electric vehicle markets, where compact and durable joints enhance reliability.

Medical device manufacturing also integrates fiber laser systems, particularly in surgical tools, implants, and micro-component assembly. Its accuracy ensures compliance with stringent safety and quality regulations.

| Industry | Example Applications | Key Benefit |

| Automotive | Body-in-white, aluminum alloy welding | Lightweight, high-strength |

| Aerospace | Turbine repairs, thin-profile joining | Reduced weight, durability |

| Electronics | Battery packs, circuit assemblies | Miniaturization, reliability |

| Medical | Surgical tools, micro-components | Precision, safety |

Emerging Advancements In Fiber Laser Welding

Technological developments are shifting the capabilities of fiber laser welding, offering manufacturers opportunities to refine processes and expand applications.

Enhanced Precision And Speed

Fiber laser welding systems now achieve tighter tolerances with improved accuracy. Advancements such as smaller spot sizes and higher beam quality enable precise control over the welding process. For example, 2 µm wavelength lasers have gained attention for better focusing on specific materials like plastics and specialty metals.

Higher repetition rates, reaching up to 50 kHz in some systems, allow faster production without sacrificing weld quality. In industries such as electronics manufacturing, where thin or delicate materials like foils and wires are common, this precision supports high-yield and low-reject operations.

Integration With Automation And Robotics

Seamlessly combining fiber lasers with robotic automation has become more feasible. Multi-axis robotic arms paired with fiber laser heads simplify complex weld profiles across automotive assembly lines. These robotic systems track intricate geometries to weld without manual intervention.

Vision systems embedded within automated setups provide real-time adjustments, correcting alignment or offsets during operation. For instance, a high-resolution camera detects surface inconsistencies, helping maintain welding accuracy on reflective materials like copper or aluminum.

Development of New Materials Compatibility

Expanding the range of materials used in fiber laser welding showcases ongoing research. Recent innovations enable joining dissimilar materials, such as aluminum and steel, in lightweighting projects. Ytterbium-doped fibers’ tunable wavelengths help overcome reflectivity issues in these materials.

Manufacturers using nickel-based alloys or titanium for aerospace now benefit from enhancements in weld quality, reducing post-processing steps. Developers are exploring specialized coatings and laser parameters for processing high-heat-resistant ceramics and composites, boosting their functionality in extreme environments.

Industry-Driven Innovations

Manufacturers are driving advancements in fiber laser welding, aligning new technologies with industry demands. These innovations focus on improving operational efficiency, reducing costs, and incorporating smarter systems for enhanced productivity.

Improved Energy Efficiency

Fiber laser welding systems are becoming more energy-efficient, driven by increasing environmental standards and rising energy costs. Modern designs—like those from Denaliweld—lower power consumption while maintaining output quality. For example, systems now achieve wall-plug efficiencies exceeding 40%, surpassing traditional gas lasers’ efficiency of 20–30%. This advancement offers significant savings over time, especially in high-load production environments.

Energy-efficient fibers generate less waste heat during operation, minimizing cooling requirements. Compact cooling setups, such as those integrated into portable systems, reduce infrastructure demands. By focusing resources more effectively, this efficiency lowers overall operational expenses and environmental impact.

Cost-Effective Solutions For Manufacturers

Modern modular fiber-laser platforms let manufacturers begin with compact, scalable setups that slash installation costs and expand easily through plug-and-play upgrades, avoiding full equipment overhauls. Their space-saving designs reduce material use and suit precision industries that need frequent adjustments. At the same time, diodes rated beyond 100,000 hours and lower energy demands further cut operating expenses, making fiber-laser welding a cost-effective choice for small- and medium-scale production.

Adoption of AI And Machine Learning

AI-driven fiber laser welding now uses real-time sensors and algorithms to track parameters such as beam intensity, speed, and alignment, automatically correcting deviations to cut defects in precision jobs like battery and microelectronic assembly. The same data powers predictive maintenance that flags component wear before failure, avoiding downtime and lengthening part life. At the same time, machine-learning models fine-tune settings for diverse materials—including dissimilar joins—so welds show less porosity or cracking even in demanding aerospace applications. These advances mark a move toward smart, adaptable welding that optimizes quality, efficiency, and equipment longevity.

Preparing for the Future

Adaptability shapes the long-term success of fiber laser welding in manufacturing. Anticipating advancements and responding strategically helps sustain competitiveness.

| Focus Area | Description |

| Investing in Cutting-Edge Technologies | Acquire modular, scalable fiber-laser systems so upgrades stay affordable as hardware and software advance. After evaluating suppliers, combine these with integrated vision and >40 % wall-plug-efficient units to reduce defects and energy costs. |

| Upskilling the Workforce | Deliver focused training on modern laser programming and automated welding paths for technicians and operators. Reinforce skills through vendor-led workshops and cross-training in material science and robotics to improve calibration, maintenance, and system integration. |

| Collaboration Across the Industry | Engage with trade associations, technical consortia, and material suppliers to share insights on novel welding methods and alloy compatibility. Attend expos and conferences to spot emerging optics and control solutions while expanding peer networks. |

Conclusion

The future of fiber laser welding holds immense potential for manufacturers ready to embrace innovation. You can unlock new efficiencies and expand your capabilities by staying ahead of advancements like automation, AI integration, and material compatibility.

Investing in cutting-edge technologies and fostering collaboration across the industry will position your business for long-term success. As market demands evolve, adaptability will be your greatest asset in leveraging fiber laser welding to drive growth, reduce costs, and meet sustainability goals.