A composite insulator in the power transmission and distribution industry is specially designed to offer optimal performance and reliability. Compared to traditional porcelain insulators, these modern devices are crafted from a blend of polymeric materials. They possess unique features such as high mechanical strength, outstanding resistance to harsh conditions, and excellent electrical insulation.

Understanding various insulator types and applications is significant to selecting the right device for your requirements. Let’s explore common kinds of insulators and their practical usage in electrical systems.

Common Types of Insulators in the Market

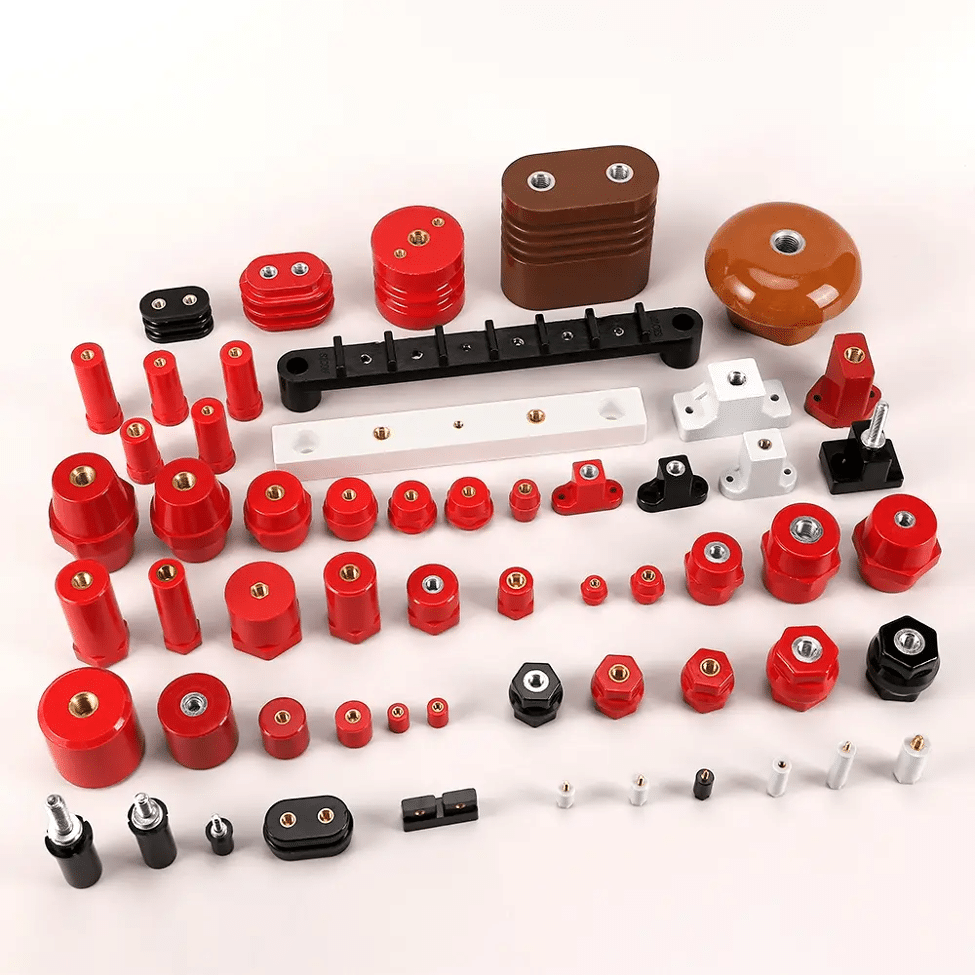

In the market, composite insulators are categorized based on the type of resin used in their construction. Here are the common types:

Thermoplastic Resin Insulators

Thermoplastic resin insulators are plastic polymer material that softens upon heating and solidifies when subject to cool temperature. Their ability to change shapes multiple times without deterioration makes them versatile for various applications. Among thermoplastic resin insulators, the most notable type is the Polyamide Insulator.

Polyamide, commonly known as nylon, is a popular thermoplastic used in insulators due to its exceptional properties. It encompasses high mechanical strength, flexibility, and resistance to abrasion and chemicals. However, the nylon insulator has low high-temperature resistance, where it is appropriate to apply it in around -30°C~+80°C environment.

Thermoset Resin Insulators

Thermoset resin insulators are made of cross-linked polymer material that keeps their shape intact once hardened. This means that they cannot be remelted or reshaped during healing and have high thermal stability. Some of the thermoset composite insulator types are as follows:

1. PF Insulators

Phenolic Formaldehyde (PF) insulators, crafted from a thermosetting resin produced by the polymerization of phenol and formaldehyde, are commonly recognized in the industry under the term “bakelite.” These insulators are economically priced and prevalently used across the electronics sector due to their cost-effectiveness and the ease with which they can be manufactured, often resulting in a high rate of acceptable products. With a smooth and polished surface, PF insulators offer aesthetic appeal alongside practical utility.

Despite these advantages, this composite insulator exhibits considerable high-frequency losses, which restricts its effectiveness in low-frequency environments such as power and audio frequency applications. They do not incorporate fiberglass, which contributes to their increased brittleness.

Additionally, PF insulators demonstrate suboptimal electrical properties under elevated temperatures, with an operational temperature range spanning from -25°C to 105°C. Due to these characteristics, they are primarily suited for use in standard electrical cabinets where conditions do not exceed these specified limits.

2. EMC Insulators

The Epoxy Molding Compound (EMC) insulator is a versatile and robust component used widely in environments that demand high mechanical integrity and durability. Initially thermoplastic, epoxy resin undergoes a transformation to a thermosetting form under the influence of various curing agents. This change enhances its mechanical properties and thermal resistance, making it well-suited for challenging conditions.

And EMC insulators are characterized by excellent dielectric properties, along with resistance to water, moisture, cold, and chemical corrosion, making them highly reliable in adverse environments. Additionally, they are capable of withstanding high-voltage arcs and corona discharges, which are critical factors in electrical applications.

The inclusion of quartz in the epoxy molding compound significantly increases the surface hardness, lends a high-gloss finish, and prevents the accumulation of dust. This makes this kind of composite insulator particularly effective in confined spaces where mechanical performance is critical.

Furthermore, compared to other materials, EMC insulators stand out for their superior high-temperature resistance, with an operational temperature range extending from -40°C to 200°C. This broad range makes them exceptionally suitable for applications where temperature extremes are a common challenge.

3. BMC & SMC Insulators

BMC (Bulk Molding Compound) and SMC (Sheet Molding Compound) insulators are integral components in various industries. These composite insulators are tailored for diverse molding processes, making them adaptable to meet the performance requirements of various products.

BMC insulators are manufactured using a process that involves mixing materials, which results in shorter fiberglass lengths within the compound. This characteristic enhances their strength under bending and tension compared to other insulators of similar size. The general operating temperature range of BMC insulators is from -40°C to 140°C. Their adaptability to various molding techniques allows them to meet a wide array of performance demands effectively.

In contrast, SMC insulators are produced without the mixing process used in BMC. This approach preserves the integrity of the fiberglass, maintaining its longer lengths, which significantly increases the tensile strength of the final product. SMC insulators are particularly favored for medium-voltage applications due to their superior mechanical strength and durability. Like BMC, SMC insulators can also operate within a temperature range of -40°C to 140°C.

Applications of Composite Insulator and its Significance

1. Communication Infrastructure

Composite insulators are extensively used in communication infrastructure. They support and insulate the components of transmission lines, antennas, and towers. Due to their lightweight nature and high resistance to pollution and temperature, networking industries utilize them for outdoor installations.

Wind-Power Generator Machines

Composite insulators are used in various components of wind power generation, such as transformers, switchgear, and turbine generators. Their excellent mechanical strength and resistance to harsh environmental factors ensure continuous and efficient power generation.

NEV

Composite insulators are vital in the development and operation of new energy vehicles (NEVs). They are utilized in battery packs and electrical control systems to provide necessary insulation and protection against damage. The lightweight and durable nature of composite insulators enhances the overall efficiency and safety of NEVs.

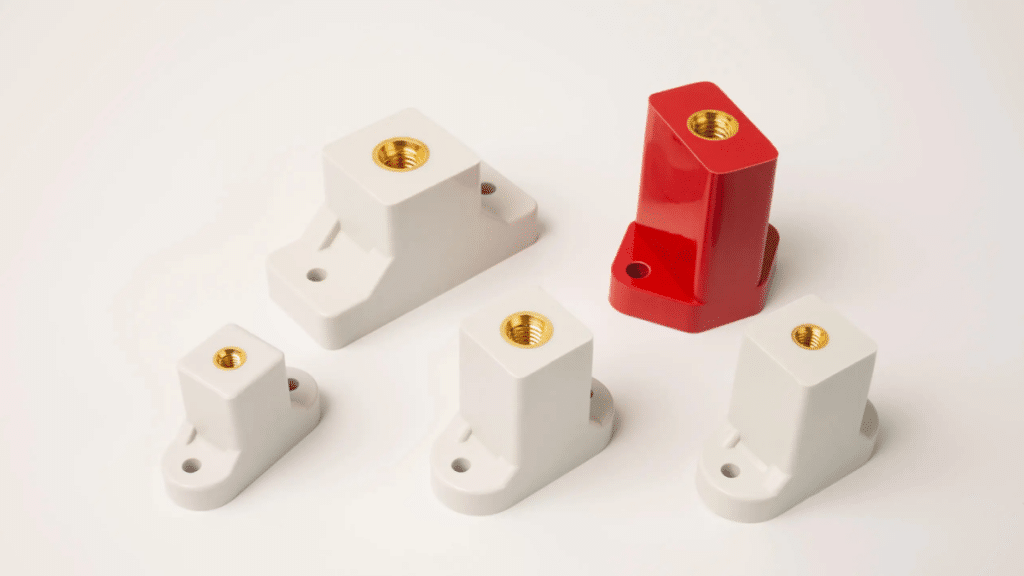

Flyaford’s Customization Service on Insulators

So, if you want to invest in a reliable composite insulator, look no further than Flyaford’s customized insulators. They are a leading insulator manufacturer company that offers a tailored service to satiate your specific requirements on composite insulators. Here’re what you can expect:

1. Diverse Customized Product Line

Flyaford specializes in providing customized insulation solutions tailored to meet specific customer requirements. With expertise in customizing a diverse range of materials, including PF, BMC, EMC, PMC, and SMC, Flyaford stands out in the industry.

2. Efficient Production Processes

The company’s manufacturing process is streamlined to achieve efficiency without sacrificing quality. Flyaford delivers a mold production cycle ranging from 30 to 60 days, demonstrating its commitment to delivering customized composite insulators swiftly.

3. Rigorous Testing and Compliance

Quality assurance is a cornerstone of Flyaford’s operation. So, they employ stringent testing procedures to ensure that all products can reach the highest standard in the industry. A key aspect of their quality control involves comprehensive ROHS compliance testing. This ensures that their products adhere to strict environmental and safety standards, providing their clients with assurance that their customized insulators are both effective and responsible.

Conclusion

In short, a composite insulator plays a significant role in modern electrical and energy systems due to their unique features. Flyaford’s customization services enhance the utility of busbar insulators and other types by tailoring them to specific needs. If you are interested, please visit Flyaford’s official website to get more information and contact them!