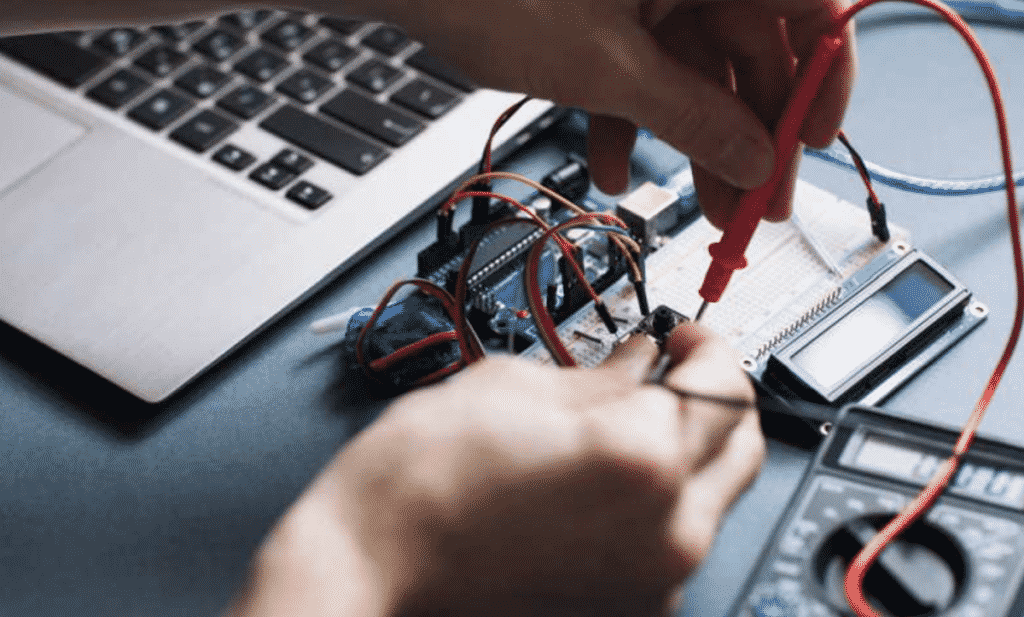

If you are designing a medical PCB, especially a prototype version of it, here are 6 hacks that will come in handy both in the interest of quality of the PCB design given the mission-critical nature of the device and the time to market.

#1. Be Prepared for Changes

This may not sound like the best advice but the fact is that if you are putting together a prototype, you have to design with modifications in mind. Some best practices to follow in this regard includes:

- Traces are accessible from the top layer– What this ensures is that it is easy to cut and scrape the solder mask

- Larger Vias– Making the vias large enough ensures that soldering jumpers to them is easy.

- Space between components– While the need to design high-density board is real, at the prototype stage, it will help to ensure there is space between components so that modifications are easier.

#2. Ensure that the board lends itself to testing

Adding a whole lot of test points on signal traces as well as on the output of power supplies comes in extremely handy for testing. Having test points on the side of the board that is exposed is yet another best practice that makes it easy to test and debug if need be.

#3. Do not design from scratch

While it may be tempting to design from scratch, in the interest of time it will work better if a sub-circuit from a previous design can be used. That way you do not have to replicate your efforts and that testing and eventually go-to-market can be that much quicker.

#4. Ensure the design lends itself to ease of assembly

It’s understandable that there is a lot of routing and re-routing that you are doing in terms of design for your medical PCB Assembly. The one thing that it will lead to, however, is that assembly will become that much tougher. Some of the aspects you need to consider include:

- The connectors are arranged well so that it is easy for the assembler to connect them to their cables

- The pads connected to ground fills have thermal relief connections so that solderability is easy.

- Having a 3D model of the board so that a virtual test fit is possible.

- Ensure screw terminal boxes for several connectors aren’t used as that will mean every terminal has to be unscrewed if the board is to be removed for debugging

These seemingly simple tips can go a long way in saving precious time and energy when it comes to assembly.

#5. When in doubt, add a footprint!

There could be a number of components that may be required at a later date but that you may not be sure of quite yet. When in doubt, the thumb rule is to put the footprint for that component, anyway. For example, if you feel a certain RC low-pass filter may be required, it will be prudent to put a zero-ohm resistor. With footprints in place, you will not have to struggle if indeed the component is required at a later time.

#6. Have ground planes

It is advisable to have ground planes on all layers stitched with vias. A word of caution here, if there are both analog and digital sub-circuits, it is best to split the ground planes to minimize noise.

While the above isn’t an exhaustive list, these best practices can go a long way in ensuring ease when you are designing something as critical as a medical device PCB prototype. In the current milieu where competitiveness is also a function of quick go-to-market, these best practices will ensure you do not waste time on repetitive work. In fact, going with a professional PCB assembly service provider offers you this advantage where your contract manufacturer has years of experience and is privy to a number of best practices that ensure that you do not have to reinvent the wheel.

What it also does is saves you from errors that can cost you time, money, and in some cases even company reputation. Especially in mission-critical PCBs where there is no scope of error, the best practices come in extremely handy.