In today’s competitive manufacturing landscape, efficiency is the bedrock upon which successful operations are built. Among the numerous metrics that factories must monitor, few are as telling as capacity utilization. This measure offers profound insights into how well a company is using its production potential to create goods. Focusing on capacity utilization can lead to improvements in operational efficiency, cost reduction, and higher profitability. Keep reading as we delve into the intricacies of capacity utilization and its impact on manufacturing practices.

Exploring the Definition and Importance of Capacity Utilization in Manufacturing

Alt text: A factory scene showcasing workers efficiently operating machines, highlighting optimal capacity utilization in production.

Capacity utilization is a crucial metric for manufacturers, indicating the extent to which their production capacity is being used over a set period. It indicates the level of wastage or efficiency within the production process. High capacity utilization rates indicate high production efficiency, leading to economies of scale. Conversely, low utilization rates indicate underutilization, suggesting room for increased production without additional capital costs.

Firms should reassess their operations to strike an optimal balance in capacity usage. Understanding capacity utilization is especially important in global competition, as businesses that maximize capacity without compromising quality are more likely to remain competitive and keep costs low.

Assessing How Capacity Utilization Impacts Manufacturing Efficiency

Capacity utilization is crucial for manufacturing efficiency, as it prevents unnecessary costs and allows for better workforce planning and allocation. It also affects cost structure and the manufacturing process’s agility, allowing factories to respond swiftly to changes in demand. However, it should not lead to over-extraction from machinery and labor, as long-term sustainability requires a balance between output levels and maintenance schedules and workforce well-being.

Over-extraction can lead to increased breakdowns and reduced morale, negatively impacting productivity and efficiency. Analyzing and adjusting capacity utilization can also improve supply chain efficiency, enabling better forecasting, inventory management, and product flow.

Techniques for Measuring Capacity Utilization in Production Environments

Manufacturers use various techniques to assess capacity utilization, including calculating the ratio of actual output to potential output, real-time monitoring of equipment and labor, benchmarking against industry standards, and predictive analytics. These methods help identify inefficiencies and areas for improvement, allowing for dynamic resource reallocation and adaptability to shifts in demand.

Comparing capacity utilization rates to similar companies or industry averages can also provide valuable insights for operational improvements. Predictive analytics, analyzing historical data and trends, allows manufacturers to forecast future capacity needs and prepare accordingly, ensuring proactive strategies are adopted.

Strategies to Optimize Capacity Utilization for Better Manufacturing Outcomes

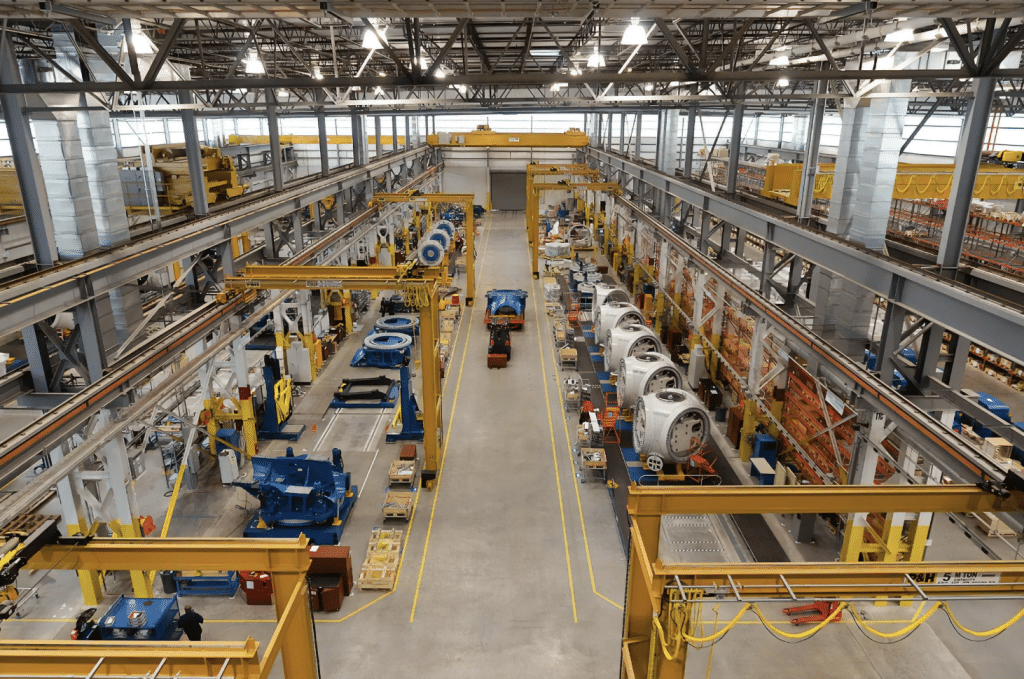

Alt text: An industrial factory scene featuring workers diligently operating various machines in a busy production environment.

Capacity utilization is a complex process that requires a balance of various factors. Predictive maintenance is a key strategy to ensure equipment operates at peak performance, minimizing downtime and maximizing production capability. Demand planning and inventory control enhance forecasting accuracy, aligning production schedules with market needs and preventing overproduction and underproduction.

Lean manufacturing principles, such as value stream mapping, eliminate waste and ensure every stage adds value without squandering capacity. A flexible manufacturing system, which allows quick switching between product lines or adjustments to demand, maximizes asset use and avoids underutilization. These strategies help optimize production and reduce waste.

The Role of Technology in Enhancing Capacity Utilization Metrics

The Industrial Internet of Things (IIoT) and Industry 4.0 have revolutionized capacity utilization by collecting vast operational data through smart sensors and IoT devices. Artificial intelligence and machine learning algorithms use this data to predict disruptions and suggest optimizations, enabling manufacturers to anticipate maintenance needs, optimize production runs, and reduce waste.

Cloud computing and storage solutions also enhance capacity utilization by allowing flexible storage and processing of operational data, facilitating better decision-making and agility in adjusting production strategies. Advanced simulation software allows managers to model changes in production lines before implementation, minimizing risk and maximizing the effectiveness of capacity utilization strategies.

Altogether, the significance of capacity utilization in manufacturing cannot be overstated. As a key indicator of efficiency, it not only impacts the bottom line but also informs strategic decisions that drive industry innovation and competitiveness. The continuous advancement of technology offers manufacturers an ever-growing toolkit for refining their capacity utilization tactics and securing a robust position in the global market.