- What flow meters do and why accurate flow measurement matters:

I’ve installed and calibrated flow meters in everything from chemical plants to municipal water systems, and I can tell you — the right meter can make or break your process. Accurate flow measurement keeps production consistent, ensures compliance, and cuts waste. - Main types: mechanical, differential pressure, electromagnetic, ultrasonic, thermal, mass:

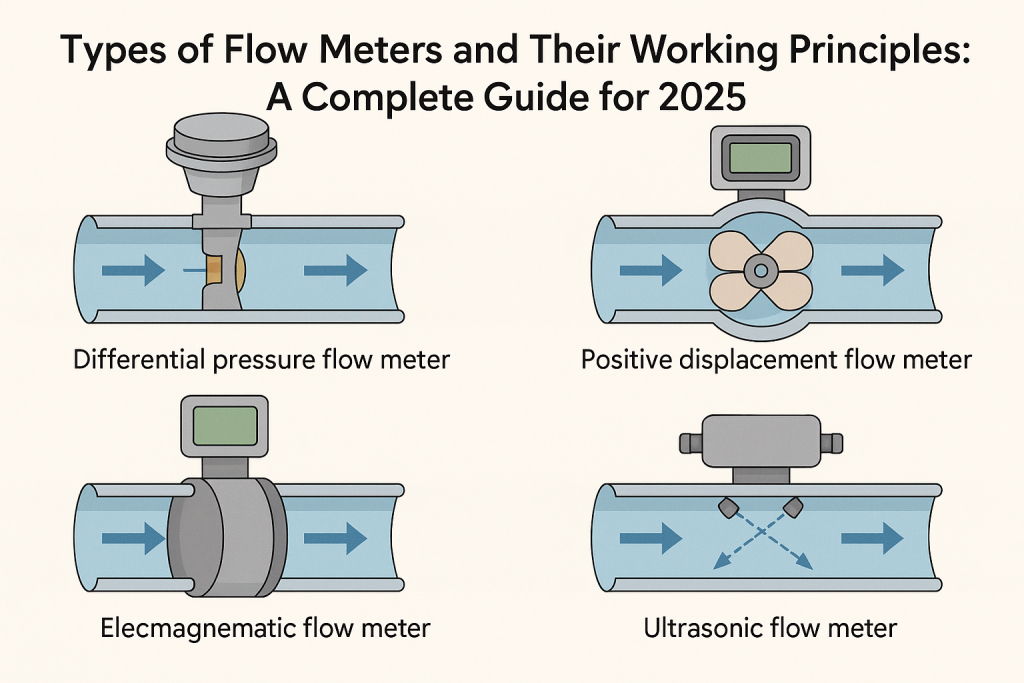

Over the years, I’ve worked with nearly every flow meter technology available. Each type — from mechanical turbine meters to Coriolis mass meters — has its own strengths and weaknesses depending on the fluid and application. - How each type works with examples and schematics:

This guide breaks down how each flow meter operates, using real-world examples and simplified diagrams. If you’ve ever wondered how ultrasonic meters measure flow without touching the fluid or why electromagnetic meters need conductivity, you’ll see it clearly explained here. - Best flow meter type by media and industry (water, oil, gas, chemicals):

I’ll show you which technologies excel in different industries. For example, electromagnetic meters for wastewater, thermal mass for compressed air, or Coriolis for high-value chemical dosing. - Diagrams, pros/cons, and real-world selection advice:

Beyond the theory, you’ll get the practical pros and cons I’ve learned on-site — which meters are easy to maintain, which fail under dirty conditions, and which are worth the extra investment. This isn’t just specs; it’s field-tested insight to help you pick the right flow meter for your system.

What Is a Flow Meter and Why Is It Important?

A flow meter is an instrument used to measure the movement of a fluid — whether liquid, gas, or steam — through a pipe or system. Depending on the technology, a flow meter can measure volume flow rate, mass flow rate, or even fluid velocity directly. In practical terms, it tells you how much product is moving at any given time, which is critical for process control, safety, and cost efficiency.

Most modern meters also offer totalizer functionality, meaning they don’t just show the current flow rate but also accumulate total flow over time. This is invaluable for tracking production output, billing utilities, or ensuring regulatory compliance in industries where every liter or kilogram counts.

Flow meters are used in a wide range of sectors:

- Water treatment plants rely on them to monitor and control incoming and outgoing water streams.

- Oil & gas facilities use them to track hydrocarbons, chemicals, and steam for both process and safety reasons.

- Pharmaceutical production demands precise flow control for ingredients and CIP (clean-in-place) systems.

- Food & beverage plants integrate flow meters to manage dosing, filling, and blending operations.

In my work, I’ve seen the difference a high-quality device can make. For example, using an E&H flow meter (Endress+Hauser) on a wastewater line dramatically improved measurement accuracy compared to older mechanical meters. E&H flow meters are known for their reliability in challenging applications — from conductive liquids to aggressive chemicals — making them a benchmark in industries where precision and durability are critical.

This combination of real-time measurement and totalizing capability is why flow meters are considered the “cash registers” of industrial processes, ensuring every drop or cubic meter is accounted for.

What Are the Main Types of Flow Meters?

Flow meters come in many varieties, each with its own measurement principle and ideal application. Below, I’ll break down the key types I’ve worked with in the field, along with how they function and where they typically perform best.

Mechanical Flow Meters

Mechanical flow meters — like turbine and positive displacement meters — rely on moving parts to measure the flow. Turbine meters use a spinning rotor whose speed correlates with flow rate, while positive displacement meters trap and count discrete volumes of fluid.

They’re especially popular in water, oil, and fuel applications where the fluid is clean and consistent. I’ve installed PD meters on diesel lines and turbine meters on irrigation systems — simple, rugged, and easy to read. Just keep in mind they need maintenance due to wear and tear.

Differential Pressure Flow Meters

These meters calculate flow by measuring pressure drop across a restriction, such as an orifice plate, Venturi tube, or flow nozzle. The higher the flow, the bigger the pressure differential.

DP meters are a staple in process plants — cheap, standardized, and well-understood. But in my experience, they can struggle with dirty or viscous fluids, where buildup or changing flow profiles distort accuracy. Maintenance and calibration are key.

Electromagnetic Flow Meters

Electromagnetic (mag) meters operate on Faraday’s law, where a moving conductive fluid in a magnetic field generates a voltage proportional to flow.

These are ideal for conductive liquids like water, acids, slurries, and even sewage. I’ve used E&H mag meters in chemical dosing skids and water treatment tanks with great results. The best part? No moving parts, which means minimal maintenance and long-term reliability — as long as the fluid is conductive.

Ultrasonic Flow Meters

Ultrasonic meters use sound waves to measure flow. Transit-time versions compare signals traveling with and against flow direction; Doppler types detect frequency shifts caused by moving particles or bubbles.

What I love about ultrasonic meters is the non-invasive option — clamp-on sensors that attach outside the pipe, perfect for temporary monitoring or hard-to-reach places. They’re widely used in HVAC, wastewater, and energy audit applications.

Comparison of Flow Meter Types

Choosing the right flow meter often comes down to a trade-off between accuracy, cost, and application fit. Here’s a practical comparison based on my hands-on experience with various flow technologies across water, gas, and industrial fluid systems:

| Technology | Best For | Fluid Type | Accuracy | Maintenance Level | Cost Range | Pipe Size Compatibility |

| Mechanical (Turbine / PD) | Clean water, oil, simple batching systems | Liquid (clean, non-corrosive) | Moderate to High | Medium (wear-prone) | Low to Medium | Small to Medium |

| Differential Pressure | Utilities, general-purpose industrial lines | Liquid, steam, gas | Moderate | Medium (prone to clogging) | Low | Wide range (with proper fittings) |

| Electromagnetic | Water treatment, chemicals, slurries | Conductive liquids only | High | Low (no moving parts) | Medium to High | Medium to Large |

| Ultrasonic (Transit / Doppler) | Non-invasive installs, energy audits | Liquid (clean or dirty) | Moderate to High | Low | Medium to High | Small to Extra Large (clamp-on) |

| Thermal Mass | Gas flow monitoring in HVAC, labs | Gases only | High (for clean gas) | Low | Medium | Small to Medium |

| Coriolis | Pharma, food, high-value liquids | Liquid & Gas | Very High | Low (but complex) | High | Small to Medium |

This table should help you quickly assess which flow meter suits your process — whether you’re measuring chilled water in an HVAC loop, batching fuel, or dosing expensive fluids in a food plant. In most industrial setups, I start with electromagnetic or DP meters and only go for Coriolis when extreme precision is required.

How to Choose the Right Flow Meter for Your Application

Selecting the right flow meter isn’t just about picking the most accurate one — it’s about choosing what fits your system, fluid, and budget. I’ve helped spec flow meters in everything from water plants to gas skids, and here’s the step-by-step process I use in the field:

- Know Your Fluid

Start by identifying what you’re measuring. Is it clean water, sludge, steam, air, or a corrosive chemical? Electromagnetic meters need conductive fluids. Thermal and Coriolis meters are best for gases or dense liquids. Dirty or viscous media may clog mechanical or DP meters. - Define Accuracy Needs and Flow Range

If you’re doing custody transfer or batching expensive liquids, go for Coriolis or magmeters. For general process monitoring, moderate-accuracy solutions like ultrasonic or differential pressure may suffice. - Match Pipe Size and Installation Constraints

Clamp-on ultrasonic meters are great for retrofits where you can’t shut down the line. Mechanical meters may require straight runs upstream/downstream. Check the sensor’s installation length and if it can fit your piping layout. - Check Output Signal and Controller Compatibility

Know what your PLC or SCADA system accepts: 4–20 mA, pulse, HART, Modbus? Some smart meters also offer diagnostics or Bluetooth setup — great for remote monitoring. - Balance Budget vs Maintenance

Mechanical meters are cheaper upfront but can wear out. Electromagnetic and ultrasonic meters have no moving parts and last longer, with lower maintenance. Coriolis offers the best performance, but at a premium price. - Verify Approvals and Certifications

If you’re in food, pharma, or hazardous areas, you’ll need specific certifications — like FDA, EHEDG, or ATEX. Always check local compliance requirements before ordering.

By following this checklist, you’ll avoid overengineering and get a flow meter that delivers reliability and ROI. When in doubt, I always recommend testing a demo unit under real flow conditions — especially for critical or high-variability applications.