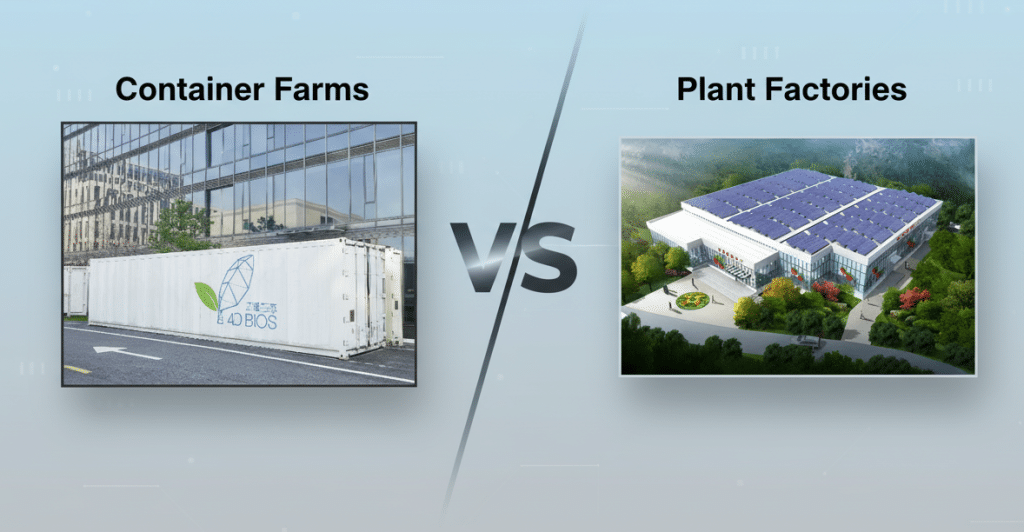

Traditional agriculture faces immense pressure. Challenges like climate change, land scarcity, and massive water consumption threaten global food security. In fact, agriculture occupies nearly half of the world’s habitable land and consumes around 69% of its freshwater [1]. In response, Controlled Environment Agriculture (CEA) has emerged as a powerful solution. CEA allows for consistent, high-yield production indoors, safe from external volatility. The CEA market is growing rapidly as a result [2]. Within this sector, two models stand out: container farms and large-scale plant factories. Both approaches offer innovative ways to grow food efficiently, yet they serve very different business needs. Understanding their strengths, limitations, and ideal applications helps agribusinesses choose the best path forward.

Container Farms: Compact, Flexible, and Fast to Deploy

At their core, container farms are self-contained growing systems built from standardized shipping containers. Inside, crops thrive through hydroponic or substrate-based systems, supported by automated climate control, LED lighting, and irrigation technologies. These mobile “vertical farming containers” are engineered for simplicity and efficiency.

One of the biggest advantages of container farms is portability. Since each unit is self-sufficient, they can be shipped and installed almost anywhere — from urban centers to remote areas. This flexibility makes them ideal for regions facing land shortages or extreme climates. Businesses can start small and expand gradually, as each container operates as a modular farming unit.

Scalability is another advantage. Companies can add more units based on market demand without the need for large capital investments upfront. For businesses that value speed, container farms can be operational within weeks, drastically shortening the time to market. They also offer a smaller environmental footprint, consuming less water and space compared to traditional farms.

However, container farms do have limitations. Their limited internal volume restricts how many plants can be grown, which can affect overall yield and production density. Energy use per unit of produce may also be higher compared to large-scale facilities.

Despite these constraints, container farms excel in niche applications:

- Restaurants or hotels seeking a fresh, on-site supply of herbs and greens.

- Community agriculture programs and educational institutions.

- Farming operations in extreme climates (like deserts or arctic regions) where traditional building is difficult.

- Disaster relief zones requiring a rapid deployment of fresh food production.[3]

Plant Factories: Industrial-Scale Precision Farming

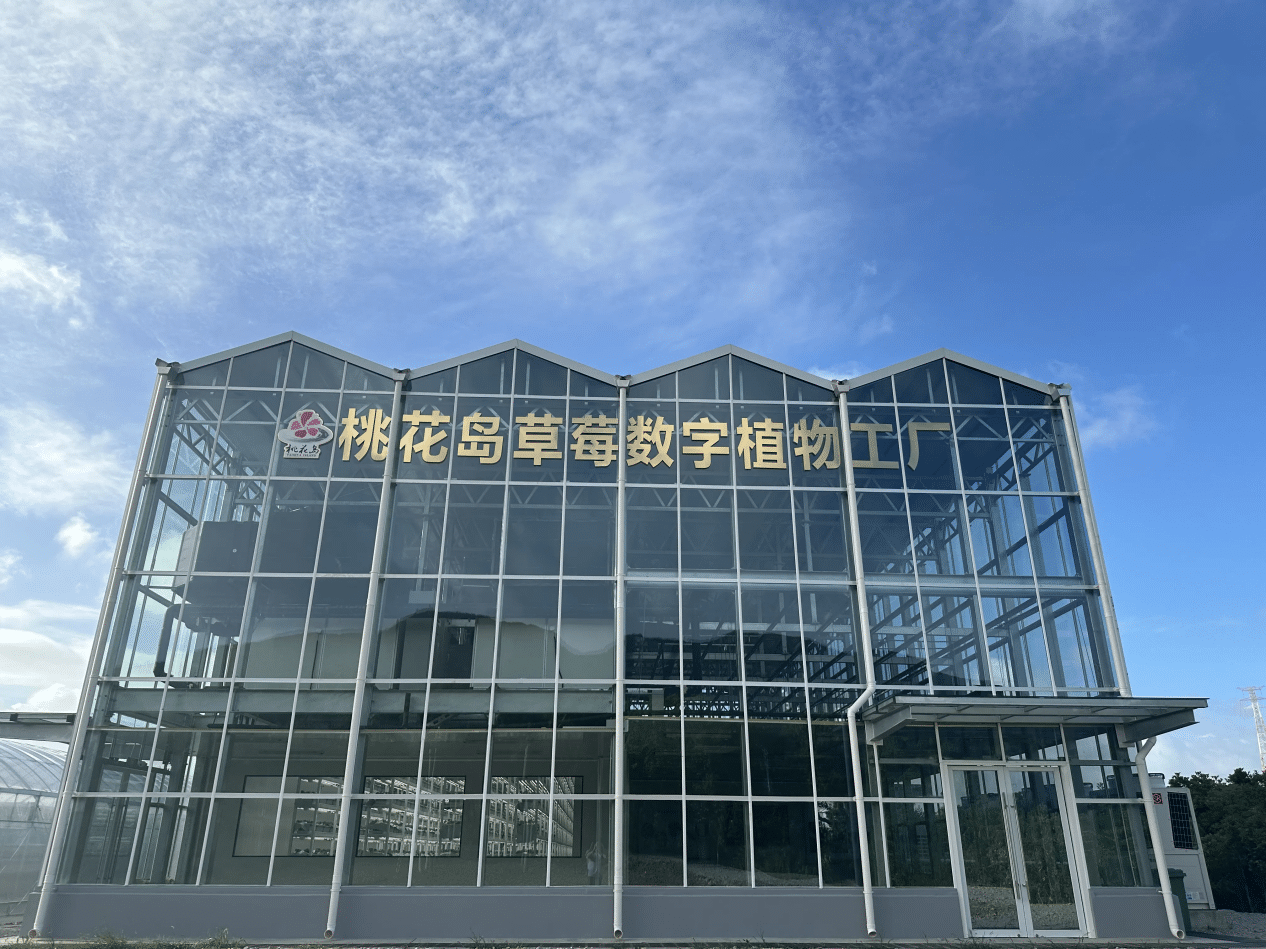

Plant factories represent the larger-scale, industrial evolution of indoor farming. Unlike mobile container farms, these are fixed, purpose-built facilities — often resembling warehouses or multi-story buildings. Inside, crops grow in carefully controlled environments using growth modules, nutrient circulation systems, HVAC, and sophisticated LED lighting technologies. The design focuses on maximizing vertical space, enabling thousands of plants to grow simultaneously in stacked layers.

The advantages of plant factories lie in their production capacity and efficiency. By controlling every aspect of the environment, they ensure consistent, year-round yields and significantly higher crop density. This makes them ideal for mass production — from leafy greens and herbs to strawberries and even herbal extracts.

At scale, operational efficiency improves, reducing the per-unit cost of production over time. Plant factories can also support diverse crop portfolios, accommodating both high-value crops and staple ingredients for food manufacturing.

The downsides, however, are notable. Initial capital investment is substantial, covering construction, lighting, climate systems, and automation. These facilities also require stable energy sources and professional management teams. Unlike container farms, they are fixed in location, which limits flexibility. For this reason, they are more suitable for:

- Large-scale manufacturing of ingredients, such as fodder for livestock or specific herbal compounds.

- Supplying major grocery distribution networks with consistent, large volumes of vegetables or strawberries.

- Serving as the core of a comprehensive agricultural park or a regional food hub.

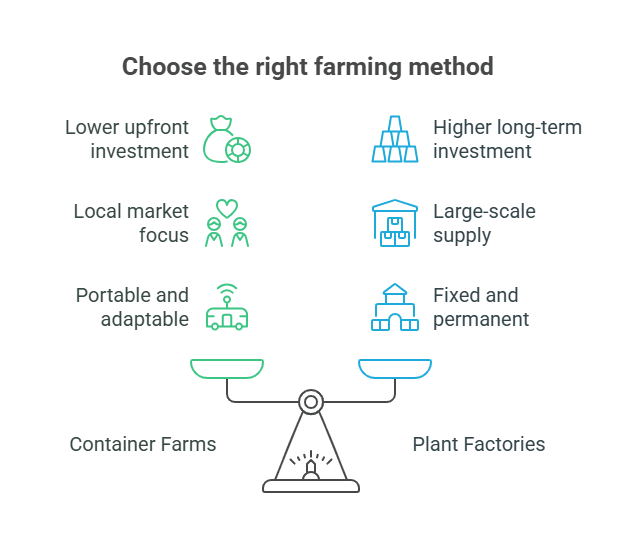

Direct Comparison: Which Fits Your Agribusiness?

Choosing between these two models comes down to balancing capital, scale, and market strategy. Here’s a table to show you the differences between the two more clearly:

| Feature | Container Farm | Plant Factory |

|---|---|---|

| Initial Capital | Low to Moderate | Very High |

| Scalability | High (Modular, add one unit at a time) | Low (Fixed building size) |

| Yield Volume | Low to Moderate (per unit) | Very High (Mass production) |

| Ideal Location | Any (Urban, remote, extreme climates) | Industrial Zone/Agricultural Parks(Fixed) |

| Time to Market | Very Fast (Weeks) | Slow (Months to Years) |

When deciding between the two, several key factors come into play:

Capital Availability

The first thing to consider is how much funding is available. For small-scale investors or those just starting out, container farms are an ideal entry point — they can be deployed quickly, require less upfront investment, and start generating returns in a short time. If the budget is sufficient, customer demand is steady, and the goal is to expand production capacity, then building a plant factory becomes a worthwhile long-term investment.

Market Demand

The next step is to understand the target market. When serving local buyers, such as restaurants, schools, or community stores, container farms can offer freshness, flexibility, and traceable supply. However, if the business aims to supply large retailers or distributors, plant factories provide the scale and consistency needed to meet bulk orders and maintain stable contracts.

Real Estate

Finally, location and space availability play a major role. Container farms are highly adaptable. Their portability allows quick relocation when business opportunities shift. Plant factories, by contrast, require a fixed location with sufficient space, stable energy, and efficient logistics. Therefore, the business must factor in the long-term cost of acquiring or leasing a large property suitable for a permanent structure, complex utilities, and large-scale logistics (loading docks, parking). The location decision is irreversible once construction begins.

Conclusion

Choosing between a modular container farm and a high-volume plant factory is a strategic decision. No matter your needs, 4D Bios can provide an advanced smart agriculture solution. As a leading ag-tech innovator, it is dedicated to developing smart plant factory systems that define the future of farming. If you’re unsure which option best fits your agribusiness, don’t hesitate to contact the experts at 4D Bios to help you evaluate your needs and design the most effective solution for your agribusiness.