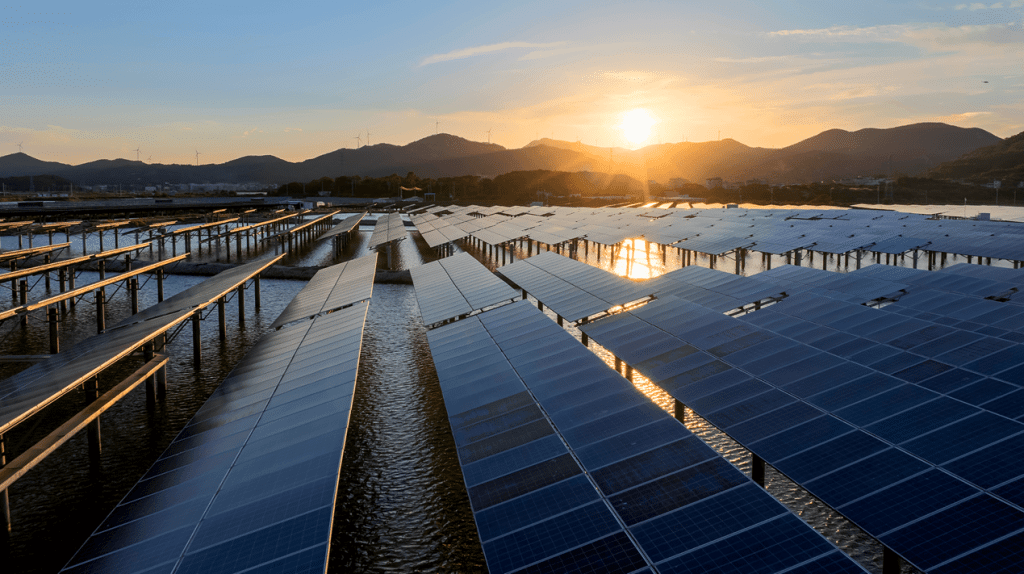

The “power generation on the water, aquaculture under the water” model, often termed aquavoltaics, represents one of the most intelligent strategies for dual land-use in the modern economy. By developing solar assets over large-scale fisheries and saline-alkali tidal flats, this approach creates a powerful hybrid solar system that addresses both land-use scarcity and the need for clean energy.

However, the success of these projects is not a given. It is entirely dependent on a specialized structural foundation. Unlike conventional ground-mount or floating PV, these intertidal or shallow-water projects require pile-driven mounting systems engineered to survive a uniquely hostile environment. The engineering challenge is immense, demanding a deep understanding of soil mechanics, material science, and structural dynamics.

Diverse Fishery-Solar Application Scenarios

The core concept of solar aquaculture is the “three-dimensional, intensive development model”. This model transforms large, open bodies of water from single-use areas into dual-revenue generators.

The primary application scenarios for these pile-driven systems are not deep, open lakes, but rather:

- Coastal Saline-Alkali Tidal Flats: These sites involve complex geological conditions and are often unsuitable for other development, making them prime candidates for dual-use energy projects.

- Inland Fisheries and Aquaculture Ponds: These areas are also well-suited for the model, where solar arrays can be installed on foundations driven into the pond beds, with aquaculture operations continuing below.

In both cases, the solar array is built on a fixed foundation, elevated above the water surface, allowing operations (like fishing or ecological management) to continue underneath.

Core Challenges of Fishery-Solar Projects

In designing for these environments, engineers must solve three critical, interconnected challenges.

1. The Geotechnical & Foundation Challenge

This is perhaps the most critical difference from dry-land solar. The substrate is not stable earth; it’s complex saline-alkali tidal flat geology. This saturated, unstable ground has poor load-bearing capacity. The primary engineering challenge is designing a foundation—typically driven piles—that can achieve long-term stability for 25+ years. This requires extensive geotechnical analysis to prevent issues like differential settlement or pull-out failure, which could cripple the array.

2. The Material Science Challenge: Extreme Corrosion

The operational environment poses an exceptionally high requirement for the equipment’s corrosion resistance. Coastal sites are classified with an atmospheric corrosion level as high as C5 —the industry’s most severe category. This is not a passive risk; it is a constant, aggressive attack from salinity and humidity. Every component, from the foundation piles to the smallest bolt, must be specified with advanced, corrosion-resistant materials and coatings to survive, as standard galvanization would fail rapidly.

3. The Structural Challenge: Extreme Dynamic & Static Loads

These projects demand extreme structural stability. Unlike inland sites that may have natural windbreaks (like hills or trees), large, flat expanses of water offer an unobstructed path for wind. The mounting structures must be engineered to withstand the full, dynamic force of Level 11 storms (wind pressure 0.60kN/m²). Simultaneously, they must support the immense static weight of heavy snow loads, specified at 40kg/m² (snow pressure 0.40kN/m²). This combination of high wind and heavy snow on a foundation set in unstable soil is the ultimate structural test.

Antaisolar’s Solutions & Innovations

The recently commissioned fishery-solar complex in Binzhou, Shandong, provides an excellent case study in how these technical challenges are solved using sophisticated pile-driven mounting systems. The complex utilized two distinct engineering approaches based on project-specific goals.

1. Binzhou Power Investment 200MW Project

For this 200MW section, the primary objective was maximizing energy yield. The implemented solution was Antaisolar’s TAI-Universal, a 2P (two-panel-in-portrait) single-axis tracker.

Technical Analysis: This system was selected for its robust design, featuring a multi-slew drive mechanical transmission. It has passed rigorous CPP wind tunnel testing, validating its resilience in extreme weather.

To combat the C5 environment and high wind loads, the design incorporates specific enhancements, such as an “improved welded integrated bearing seat + transmission shaft bracket” and a dual “bolt + pressure block” module fastening method.

From an energy perspective, the system supports large-angle tracking (±60°) and is paired with bifacial modules. This is optimized by their SmartTrail intelligent tracking algorithm, which can increase energy generation by 10-15%.

2. Xintuo & Jinhui 200MW Projects

For the 200MW Xintuo New Energy and 200MW Jinhui New Energy projects, the engineering philosophy prioritized long-term durability, simplified maintenance, and economic practicality.

Technical Analysis: For these sites, Antaisolar provided customized fixed-tilt mounting solutions. This approach represents a classic engineering trade-off, opting for mechanical simplicity and fewer moving parts to ensure maximum reliability with minimal intervention in a difficult-to-access aquatic environment.

The engineering focus for these fixed-tilt systems was on structural stability, economic practicality, and convenient installation and maintenance. The design ensures the “three-dimensional development and comprehensive utilization” of the sea and pond areas, providing a stable, long-life foundation for both power generation and the aquaculture facilities below.

Conclusion

The success of Antaisolar’s complex demonstrates that solar aquaculture on tidal flats and ponds is a viable and powerful application. However, it is fundamentally an engineering-first challenge. It proves that with robust geotechnical design, advanced material science, and sophisticated structural engineering, even the most challenging C5-level aquatic environments can be transformed into highly productive, dual-use assets.