Precision isn’t just about aiming for perfection – it’s about understanding what kind of variation is acceptable in a finished part. In CNC machining, tolerances define these acceptable limits, ensuring parts function properly without driving up unnecessary cost. Whether you’re designing a surgical device, a housing for electronics or a critical automotive component, tolerancing decisions have a direct impact on performance, cost and lead time.

Click here to explore CNC machining and see how precise tolerances can streamline your production.

What Are Tolerances in CNC Machining?

Tolerances define the allowable deviation from a specified dimension. In CNC machining, they’re often expressed as “±” values – for example, 10 mm ± 0.05 mm means the machined part must fall between 9.95 mm and 10.05 mm.

You might wonder: do I really need to think this hard about a fraction of a millimeter? The short answer is yes – because stack-up errors, fit problems or misalignments often come down to those very small differences.

There are three broad categories to keep in mind:

- General (or standard) tolerances: Used for non-critical features; usually ±0.1 mm to ±0.5 mm.

- Precision tolerances: For parts with moving assemblies or mating fits; often ±0.02 mm or tighter.

- Geometric tolerances (GD&T): Go beyond dimensions to control form orientation, location and runout.

Knowing which one to use (and where) is essential to balancing cost and functionality. Consider how your part will behave during use, not just during manufacturing.

Why Tolerances Matter More Than You Think

Tight tolerances may sound impressive, but they often add cost and complexity. Here’s why:

- Tool wear becomes a factor: Ultra-tight specs demand consistent cutting performance, which increases tool changes and machine maintenance.

- Slower machining speeds: Higher accuracy typically requires lower feed rates.

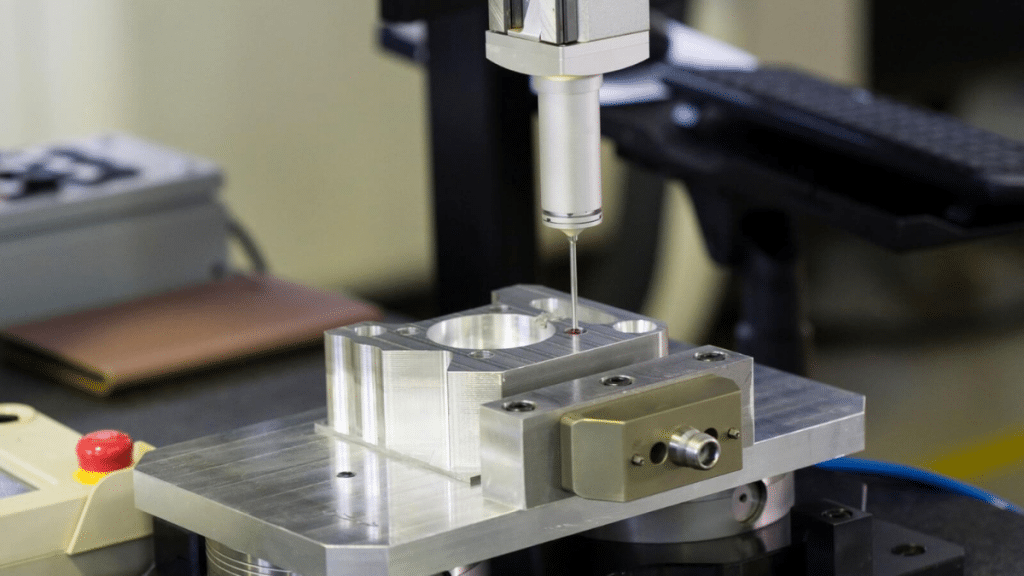

- More inspections: Each part may need to be individually checked using CMMs or other metrology tools.

The key takeaway? Not every feature needs to be highly precise. Over-specifying tolerances is one of the most common (and costly) design mistakes.

Ask yourself:

- Is this feature critical to function or assembly?

- Does it interface with another component?

- Will a minor deviation affect performance or safety?

If the answer is no, it probably doesn’t need to be held to a 0.01 mm tolerance. Save those specs for where it really matters – such as sealing surfaces, bearing fits or alignment pins.

Common Tolerancing Standards and What They Mean

If you’ve worked with technical drawings, you’ve likely seen tolerances that follow standards like ISO 2768 or ASME Y14.5.

- ISO 2768: Often used for general tolerances when not specified directly. It divides tolerances into four classes – fine, medium, coarse and very coarse – based on feature size.

- ASME Y14.5: Includes GD&T symbols and principles to define geometric relationships, ensuring better control over part features.

Understanding which standard applies (and how it will be interpreted by the machinist) ensures your part is manufactured as intended – no more, no less. Don’t assume your fabricator will guess your intent; document clearly.

Functional Fit vs. Manufacturing Fit

Let’s say you’re designing a shaft that needs to spin inside a bore. Do you need a tight press fit or a loose sliding fit? The tolerancing you choose will determine that.

These are commonly used mechanical fits:

- Clearance fit: The parts will never interfere (e.g., a drawer slide).

- Interference fit: Parts are meant to be press-fit or bonded (e.g., bearings).

- Transition fit: A balance between clearance and interference, depending on tolerances.

When in doubt, prototype both extremes. A bore with a ±0.05 mm tolerance may work perfectly with one vendor’s equipment but jam with another’s. Good DFM practices always test the limits. Communicate your fit expectations early and validate with real-world trials.

How Material Affects Tolerance

Not all materials behave the same under machining stress. Metals like aluminum or brass are easier to machine to tight specs than thermoplastics, which may deform under cutting force or thermal expansion.

Things to consider:

- Plastic parts tend to need looser tolerances – think ±0.2 mm or more.

- Harder metals can cause tooling deflection, affecting tolerance stability.

- Temperature sensitivity matters – especially for high-speed applications or where sterilization is involved.

Also consider post-machining treatments like anodizing or heat treating, which can cause dimensional shifts. The more thermally or chemically intensive your process, the more careful you’ll need to be about setting realistic specs.

The Tolerance Stack-Up Problem

Even if each individual part falls within spec, the assembly as a whole can still fail if cumulative tolerances aren’t considered.

Example: You’re designing a modular enclosure made of six milled plates. Each plate is within ±0.1 mm. That means the total variation in final assembly could be 0.6 mm – which might break your fit.

How to avoid this:

- Use datums consistently in your drawings.

- Limit the number of critical dimensions in chain assemblies.

- Plan assembly processes to accommodate the worst-case scenario.

Also factor in how parts are assembled – manual vs. automated processes may introduce their own variability.

Best Practices When Specifying Tolerances

- Don’t copy-paste tolerances from similar parts. Start fresh with each new design.

- Collaborate with your machinist before finalizing drawings. They’ll catch overspec’d features and suggest alternatives.

- Use GD&T where necessary, especially for features like holes, slots or bosses that align during assembly.

- Define inspection criteria up front – which dimensions are critical? Which can vary?

Include tolerance notes in your 2D drawings, not just the CAD file. A well-annotated drawing saves time and reduces miscommunication.

A good rule of thumb: the tighter the tolerance, the more conversation you should have with your manufacturing partner.

Final Tip: Prototypes Are Tolerance Training Wheels

Prototyping is the best place to learn how your tolerances hold up. During this phase, you’ll see which features are forgiving – and which aren’t.

Use early iterations to test your assumptions:

- Are mating parts clicking together or binding?

- Are gaps visually noticeable?

- Do parts hold position under stress or temperature swings?

And remember, even slight adjustments at this stage – like increasing a bore by 0.1 mm – can save weeks in final production. Testing tolerance ranges during prototyping gives you confidence when scaling.

Understanding tolerances isn’t just about numbers on a drawing. It’s about designing parts that work as intended – without overburdening the process. When you strike that balance, everything from unit cost to compliance becomes easier to manage across your production lifecycle.