In today’s competitive market, manufacturing businesses are embracing innovative tools to streamline operations, enhance product quality, and boost sustainability. Intelligent search solutions and plastic pipe caps stand out as key focuses. Let’s explore how these tools transform manufacturing efficiency and sustainability efforts.

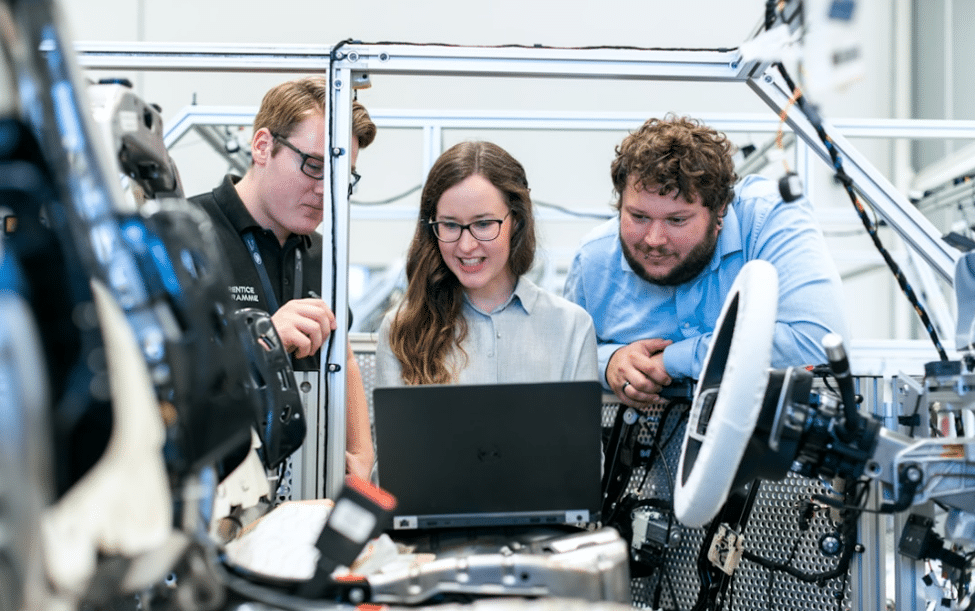

Streamlining Operations: Harnessing Intelligent Search Solutions in Manufacturing

Manufacturing enterprises are recognizing the untapped potential of intelligent search solutions to transform their operational efficiency. One of the primary benefits of using intelligent search in this context is its ability to sift through vast databases and disparate data sources, rapidly bringing forward the most relevant information. This ensures that knowledge managers and technicians can access the right answer or insight to their query, significantly reducing the time spent searching for specific information.

Intelligent search technologies utilize NLP and AI algorithms to comprehend natural language queries, including synonyms and related terms. By understanding user intent, they deliver relevant results from diverse data sources, optimizing decision-making in manufacturing businesses.

Manufacturing operations benefit from the versatility of advanced search platforms, which seamlessly integrate various data sources like document management systems and cloud infrastructures. This unified approach enhances user experience and facilitates the generation of actionable insights, leading to improved inventory management, optimized maintenance schedules, and increased customer satisfaction.

Enhancing Efficiency: Safeguarding Product Quality with Plastic Pipe Caps

In manufacturing, safeguarding product quality is paramount for maintaining customer trust and achieving market success. One overlooked but vital aspect in achieving this goal is the utilization of plastic caps for pipe, which play a crucial role in protecting components during shipping and storage. Let’s explore how these small yet effective accessories contribute to operational excellence.

Plastic pipe caps are designed to fit snugly over the ends of pipes, tubes, and other cylindrical objects, offering a level of protection that is essential for maintaining the quality of the product throughout the logistics chain. Made from polyethene and LDPE, these caps are durable and flexible, capable of withstanding rough handling while providing a tight seal against external threats. Their simplicity and effectiveness make them an indispensable tool for manufacturers looking to enhance efficiency in their operations.

Moreover, the diverse range of sizes and types available, including caps for NPT threads and various metric sizes, ensures that there is a fitting solution for every application. Whether it’s for the gas industry, plumbing, or any other field requiring the transportation of sensitive components, plastic pipe caps offer a straightforward yet powerful means to protect valuable products. By integrating such seemingly minor components into their quality control processes, manufacturers can significantly reduce the risk of damage and increase customer satisfaction, underscoring the importance of attention to detail in the pursuit of operational excellence.

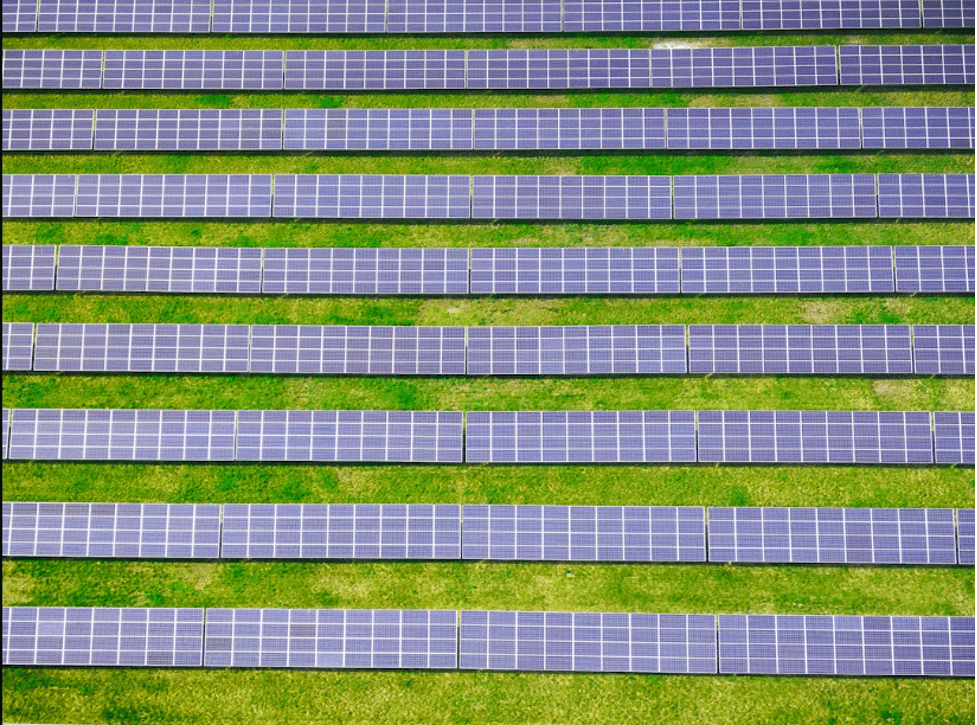

Maximizing Sustainability: Innovations in Eco-Friendly Manufacturing Solutions

Innovations in eco-friendly manufacturing solutions are reshaping how businesses approach sustainability, with an emphasis on reducing environmental impact while maintaining operational efficiency. By streamlining the retrieval and analysis of enterprise information, intelligent search applications contribute to this trend by optimizing resource use, avoiding unnecessary duplication of efforts, and improving decision-making speed. Such efficiency not only lowers energy consumption but also aligns with the broader objectives of sustainable manufacturing practices.

Furthermore, the integration of durable and reusable materials in manufacturing signifies a significant stride towards sustainability. This duality ensures that manufacturers can safeguard product quality during transport and storage without compromising their commitment to environmental stewardship.

Last but not least, the commitment to eco-friendly manufacturing extends beyond the adoption of sustainable materials and intelligent technologies. It encompasses a holistic review of production methodologies, from leveraging cloud infrastructure to minimize the carbon footprint of IT operations, to implementing intelligent enterprise search platforms that facilitate better data management and reduce wastage of resources. Let’s explore how these measures underscore the manufacturing sector’s pivotal role in advancing sustainable business practices that benefit both the planet and the bottom line.

Overall, the convergence of intelligent search solutions and the utilization of plastic pipe caps underscores the manufacturing sector’s commitment to operational efficiency and product quality. These tools streamline operations, enhance efficiency, and contribute to sustainability by minimizing resource wastage and reducing environmental impact. By embracing these innovative technologies and practices, manufacturing businesses can navigate the competitive landscape while fulfilling their responsibilities towards customers and the planet.