LIGNA is one of the world’s leading trade fairs for woodworking manufacturing and wood processing plants, machinery, and tools, attracting thousands of visitors and exhibitors around the world. This year, the exhibition will be held from 26th to 30th May 2025 in Hannover, Germany, marking the 50th anniversary of the event since its inception in 1975.

Among the exhibitors, Huahua will be presented to showcase its latest CNC wood manufacturing solution for global woodworking machine suppliers. Headquartered in Foshan City, Guangdong Province, Huahua has specialized in CNC panel saws, wood drilling machines, automatic edge banding machines, and intelligent production lines since 2003. With over 20 years of experience, Huahua highlights the commitment to engaging with a global clientele and advancing intelligent woodworking manufacturing solutions within the woodworking sector.

Details on Huahua’s Presence at LIGNA 2025

Huahua has designed its exhibition space as an immersive experience, bringing cutting-edge CNC woodworking technology directly into your hands. Whether you’re scouting for your next production line upgrade or simply curious about the latest in smart manufacturing, you’ll find ample opportunity to engage, learn, and test-drive.

Key Details

- Dates: May 26–30, 2025

- Venue: Hannover Exhibition Grounds, Germany

- Location: Hall 11, Stand D78

- Booth Size: 154 m²

Advanced Woodworking Manufacturing Equipment on Huahua’s Booth

At the heart of Huahua’s LIGNA 2025 lies a commitment to blending longevity, accuracy, and operator protection into every solution. Two flagship systems—the CNC Panel Saw and the CNC Wood Router—showcase how thoughtful engineering upgrades can transform everyday production into a smooth, highly reliable process.

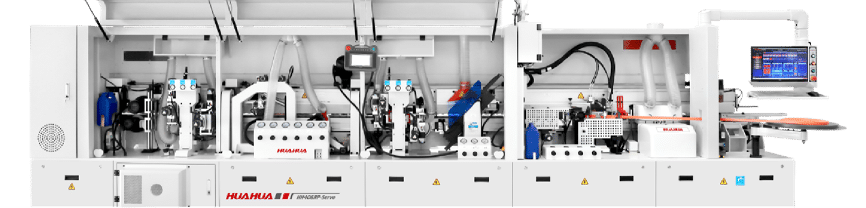

1. CNC Panel Saw—HH 406RP

Integrated Welded Base & Guide Rails

Huahua’s CNC panel saw, like HH 406RP, begins its performance edge with a monolithic frame design: the base and linear guide rails are welded into a single, unified structure. This one-piece construction virtually eliminates the micro-movement and alignment drift commonly seen in bolted-joint assemblies. The result is reliable rigidity under load, meaning that even the longest rip cuts maintain micron-level tolerances from the first panel of the day to the last.

Beyond precision, the integrated weld approach also reduces maintenance overhead. With fewer mechanical joints subject to wear, this CNC panel saw can benefit from dramatically extended service intervals. You’ll spend less time recalibrating and more time producing perfect panels, making this saw an ideal backbone for high-volume cabinetry, millwork, or panel-based furniture operations.

Flush-Level Blade with Tilting Capability

Huahua’s flush-level blade system takes scoring to the next level by allowing the scoring blade to tilt in perfect concert with the main saw blade. Instead of a fixed scoring unit that can gouge or scratch delicate surfaces when cutting at an angle, this synchronized tilting mechanism ensures the scoring blade follows the same arc, protecting laminates, veneers, and soft-face panels from unwanted damage.

Servo-Driven Three-Edge Trimming Unit

At the downstream end of the panel saw, Huahua’s servo-driven trimming module brings automatic knife adjustment with higher accuracy. Each of the three trimming blades is mounted on its own servo actuator, enabling micrometer-precise positioning via an intuitive touchscreen interface. There’s no manual crank or wrench involved: simply input your desired trimming offset, and this woodworking manufacturing machine executes flawlessly within seconds.

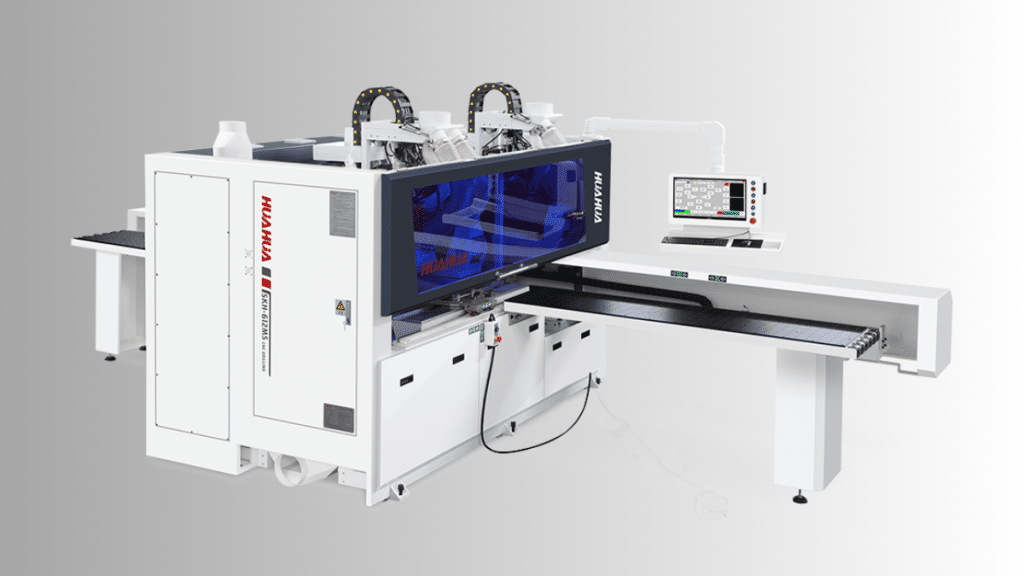

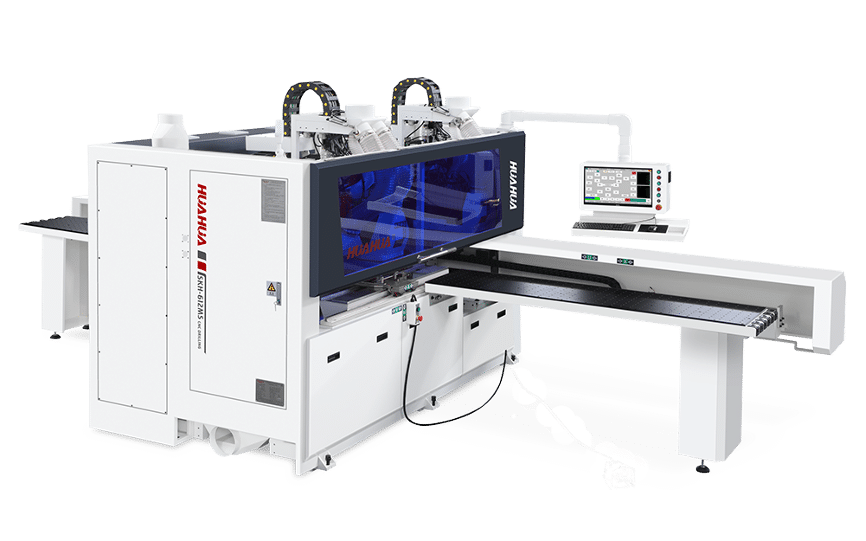

2. CNC Wood Drilling Machine—SKH-612MS

In LIGNA 2025, Huahua will unveil a series of key enhancements that make its CNC wood drilling machine smarter, safer, and more operator-friendly than ever before. One of them is SKH-612MS.

Rear-Door Interlock Safety Switch

To minimize risk during maintenance and tool changes, Huahua’s CNC wood drilling machine is now equipped with a rear-door safety interlock switch. This feature ensures that when the rear access door is opened, the machine immediately halts all mechanical motion and power to critical systems, most importantly, the drilling head.

This safety mechanism on a woodworking manufacturing machine can eliminate the chance of accidental startup during servicing. It’s a small addition with major implications for workplace safety, especially in busy, fast-paced production environments.

Full-Machine Safety Enclosure

Taking physical protection a step further, Huahua has introduced a complete safety enclosure around their SKH-612MS. The added safety fence isolates the operator from all moving parts, particularly during high-speed multi-axis drilling sequences. Designed with durable, industrial-grade materials, the enclosure acts to prevent accidental contact while maintaining clear visibility into the working area. The result is a cleaner, safer, and more controlled operating environment—an essential component for any workshop focused on safety compliance and operator well-being.

Integrated Electrical Safety Module

Internally, this woodworking manufacturing machine features a newly integrated electrical safety module, a high-level system that continuously monitors electrical performance across all critical circuits. In an era where downtime is costly, and safety is paramount, this electrical safeguard helps ensure smooth, uninterrupted woodworking manufacturing operations while protecting both the machine and its users.

Conclusion

As the woodworking manufacturing industry continues to embrace smart manufacturing, automation, and safety-driven design, Huahua stands at the forefront of this evolution. Each innovation—from servo-controlled trimming and welded-frame stability to full safety enclosures and intelligent fault detection—demonstrates Huahua’s commitment to helping manufacturers achieve higher productivity without compromising on quality or workplace protection.

So, this is why you can’t miss Huahua’s showcase at LIGNA 2025. Huahua invites global visitors to experience their innovation firsthand. For looking to upgrade a single station or modernize your entire production line, don’t miss the opportunity on Hall 11, Stand D78, to connect with Huahua’s experts, explore live demonstrations, and discover how its next-generation machinery can drive your business forward.

If you want to learn more about their solution and service, please visit Huahua’s official website or directly contact Huahua.